-

LIB Equipment

-

- Single/Double Deck High-speed Coater

- Single Deck Extrusion Coater

- Separator Coater

- Double Deck Gravure Primer Coater

- Laboratory Coater

- Separator Slitter

- Electrode Slitter

- Integrated Calendering and Slitting Machine

- Doule-side Simultaneous Coater (Laser Drying)

- Laser Notching Machine

- Metal Die-Cutting Machine

-

-

Dry Process Electrode Production Solutions

-

Solid State Battery Production Equipment

-

Hydrogen Production Solutions

-

Coating Equipment for Perovskite Solar Cells

-

KATOP Excellence Center

-

Process equipment

-

More Services

-

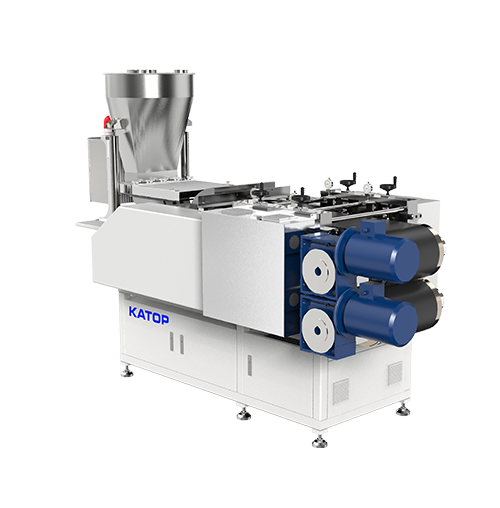

Roll-to-Roll

It is used to realize the film formation and thinning of dry electrode powder

-

Mechanical speed

MAX:1.5m/min

Roller diameter

96mm

Roller width

±2μm

-

Roller width

200mm

Effective roll width

120mm

Operating temperature

≤200℃

-

Rolling pressure

1T on one side, 2T in total, Display accuracy 0.1%

-

-

Dry Electrode Total Solution

The equipment is used for continuous dry electrode making, integrating powder mixing, feeding, film forming, thinning, double-sided lamination, rewinding, and unwinding.

-

Mechanical speed

MAX:15m/min

Operation speed

MAX:10m/min

Rolling thickness accuracy

±2μm

-

Roller width

500mm

Pressure

10~50T

Minimum tension

4N

-

-

Multi-stage Rolling Solution of Dry Electrode

The equipment is used for double-sided lamination process of cathode and anode electrode

-

Mechanical speed

MAX:15m/min

Operation speed

MAX:5m/min

Film thickness

≥70μm

-

Rolling thickness accuracy

±2μm

Roller width

400mm

Film width

300mm

-

-

Dry Electrode Steel Belt Rolling Solution

The equipment is used for hot-pressing film forming process of cathode and anode powder and bulk material of LIB

-

Mechanical speed

MAX:15m/min

Operation speed

MAX:5m/min

Film thickness

1~5mm

-

Rolling thickness accuracy

±0.5mm

Roller width

500mm

Film width

300mm

-