-

LIB Equipment

-

- Single/Double Deck High-speed Coater

- Single Deck Extrusion Coater

- Separator Coater

- Double Deck Gravure Primer Coater

- Laboratory Coater

- Separator Slitter

- Electrode Slitter

- Integrated Calendering and Slitting Machine

- Doule-side Simultaneous Coater (Laser Drying)

- Laser Notching Machine

- Metal Die-Cutting Machine

-

-

Dry Process Electrode Production Solutions

-

Solid State Battery Production Equipment

-

Hydrogen Production Solutions

-

Coating Equipment for Perovskite Solar Cells

-

KATOP Excellence Center

-

Process equipment

-

More Services

-

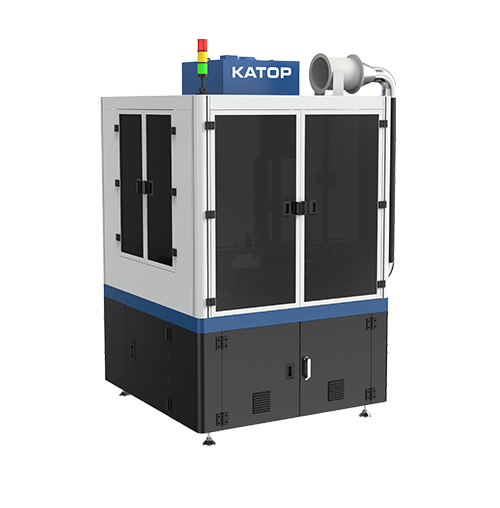

Coater for Fuel Cell Experiment

The equipment is used for fuel cell process validation and slurry formula parameter adjustment

-

Coating speed

MAX:0.6m/min

Coating speed accuracy

5‰

Coating wet film thickness range

30~100μm

-

Deviation of coating dry film thickness

± 10% (platinum load Pt)

Coating method

Slot die extrusion coating

Mechanical operation speed

MAX:12m/min

-

-

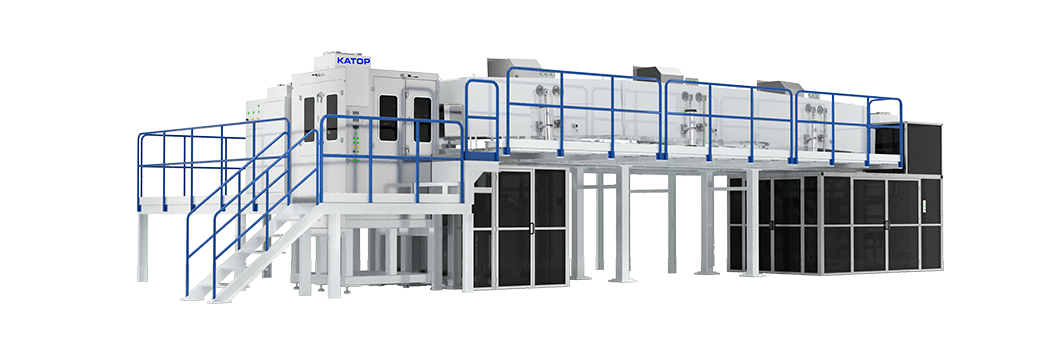

Coater for Hydrogen Production by Electrolytic Water

Applicable for the coating of electrode for PEM electrolytic water hydrogen production;

Fully automatic film ripping and covering.

-

Coating width

MAX:600mm

Coating speed

MAX:5m/min

Coating dimension accuracy

±1mm

-

Applicable substrate thickness

50~180 μm (excluding back film)

Maximum dryer temperature

MAX:150℃

Temperature control accuracy of single section of dryer

±3℃

-

-

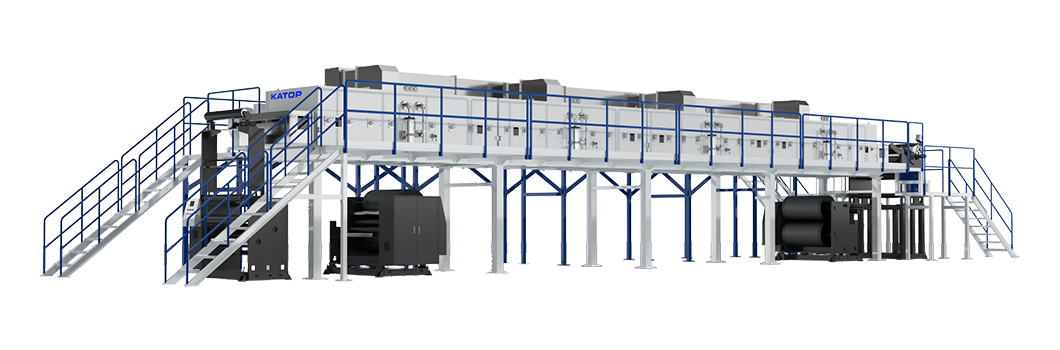

GDL Coater

Applicable to GDL carbon paper coating process, integrating unwinding, coating, drying, traction and rewinding

-

Coating width

Customized

Coating speed

MAX:5m/min

Coating width accuracy

±1mm

-

Coating wet film thickness

20~150μm

Maximum heating temperature of drying section

MAX:200℃

Maximum heating temperature of dryer in sintering section

MAX:360℃

-