-

LIB Equipment

-

- Single/Double Deck High-speed Coater

- Single Deck Extrusion Coater

- Separator Coater

- Double Deck Gravure Primer Coater

- Laboratory Coater

- Separator Slitter

- Electrode Slitter

- Integrated Calendering and Slitting Machine

- Doule-side Simultaneous Coater (Laser Drying)

- Laser Notching Machine

- Metal Die-Cutting Machine

-

-

Dry Process Electrode Production Solutions

-

Solid State Battery Production Equipment

-

Hydrogen Production Solutions

-

Coating Equipment for Perovskite Solar Cells

-

KATOP Excellence Center

-

Process equipment

-

More Services

-

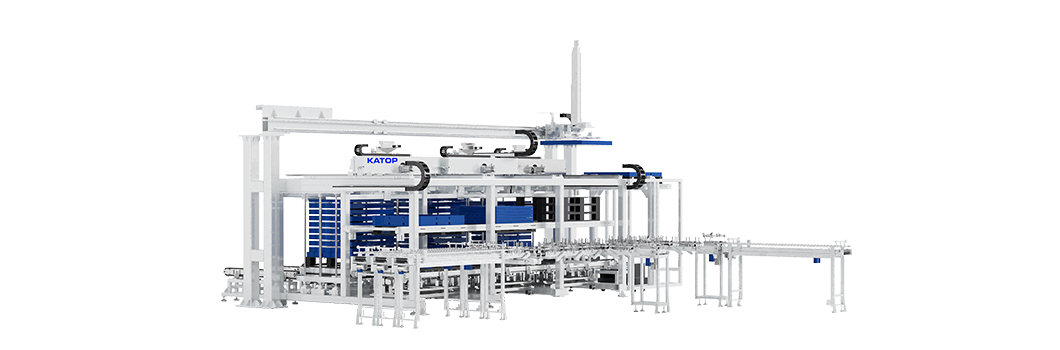

Integrated EV Cutting & Stacking Machine

The integrated EV cutting & stacking machine is designed specifically for the production of lithium battery cells for EV. This equipment integrates electrode making and high-precision stacking, significantly enhancing production quality and efficiency.

-

Overall dimension

13000 * 4800 * 2600mm

Qualification rate

≥99%

Utilization rate

≥98%

-

Single-station stacking speed

≤0.55s/pcs

Alignment accuracy of adjacent electrodes

±0.2mm

Overall alignment accuracy of electrode

±0.3mm

-

-

Integrated CE Cutting & Stacking Machine

This equipment is mainly used for the cutting and stacking of CE cells

-

Overall dimension

12000 * 5000 * 2600mm

Qualification rate

≥99%

Utilization rate

≥98%

-

Single-station stacking speed

0.5 s/pcs

Alignment accuracy of electrode

±0.15mm

Adapt to different cell size ranges

L:50~150mm W:30~120mm T:3~8mm

-

-

Front/Post Helium Detection Equipment

The equipment is used for air tightness test of aluminum power cell after welding and before filling

-

Overall dimension

6000 * 2700 * 2500mm

Qualification rate

≥99%

Utilization rate

≥98%

-

Weight

6500kg

Electrical supply

AC220V 1KW

Capacity

PPM≥20

-

-

Filling Machine

The equipment is mainly used for the filling of prismatic cell, which can realize automatic code scanning, weighing before and after filling, Hi-pot test, vacuum filling (quantitative/variable), wiping, nail insertion etc

-

Capacity

MAX:45PPM

Filling accuracy

≤ ±0.6% (filling volume1400g)

Filling volume CMK

≥1.67

-

Filling method

Efficient isobaric

Qualification rate

≥99.8%

Utilization rate

≥98%

-

-

Fully Automatic Wrapping Machine

The equipment is used for U-shaped or zigzag wrapping of prismatic cell on wide and narrow sides, and insulation test to improve battery safety

-

Overall dimension

10300 * 4500 * 2500mm

Qualification rate

≥99%

Utilization rate

≥98%

-

Capacity

PPM≥15

CMK

≥1.67

Positioning accuracy (X, Y, Z axis)

±0.1mm

-

-

Unwinding Dryer

The equipment mainly composes of unwinding, EPC, tension control, dryer, cooler and rewinding devices

-

Water content

Cathode PPM<400, Anode PPM<300

Rewinding alignment

±1mm

Maximum reel diameter/weight

≤Φ700mm/800kg

-

Foil speed

MAX:100m/min

Dryer foil length

Hot roller contact ≥ 5m,Dryer area ≥ 10m

Hot air temperature

MAX:230℃

-

-

Formation/Capacity Testing Equipment

This equipment is used for the formation, capacity grading, and performance parameter testing of lithium batteries.

-

Charging&Discharging Efficiency

10%

Energy Saving

20%

Current/voltage accuracy

±0.05% FS

-

Charge-discharge voltage range

0mV~5000mV

Maximum charging efficiency

≥90%

Maximum discharge efficiency

≥85%

-

-

Sorting & Packaging Machine

The equipment is mainly used for the grading & packaging of prismatic cells through robot and barcode scanning

-

Overall dimension

6000 * 3500 * 2300mm

Qualification rate

≥99%

Utilization rate

≥95%

-

Weight

5000kg

Capacity

PPM≥15

Compatibility range

T:12.5~17.5mm W:120~148mm H:63.5~95mm

-

Products Description

Formation and capacity sorting are critical processes in the later stages of lithium-ion battery production. The formation process activates the cell and forms a stable SEI (Solid Electrolyte Interphase) layer, followed by capacity sorting to test and select batteries based on performance, ensuring proper capacity matching and safety verification.

Integrating these two processes within the same system, such as a lithium-ion battery formation/capacity testing equipment, reduces the turnover and waiting time of batteries during production, enhancing efficiency and cutting costs. This integrated approach also ensures a seamless, consistent process, minimizing the impact of environmental changes and operational variations on battery performance, ultimately improving the quality and consistency of the final battery products.

Key Features of KATOP Lithium Ion Battery Testing Equipment

-

Environmentally Friendly Design

Equipped with automatic smoke exhaust and drainage systems that minimize pollution, ensuring compliance with global eco-regulations.

-

Fast Response & High Detection Accuracy

Achieves ±0.05% FS voltage accuracy and millisecond-level signal processing for real-time monitoring of critical parameters.

-

Automatic Fire Protection

Integrated fire suppression systems (e.g., gas detectors, rapid cutoff valves) ensure zero production accidents.

-

Constant Temperature System

Maintains optimal thermal conditions for stable SEI layer formation and long-term cycle life.

-

Real-Time Abnormality Monitoring

Tracks several critical parameters (smoke, polarity, temperature) to prevent risks like thermal runaway, with instant alerts for immediate action.

-

Universal Compatibility

Supports multi-voltage/current battery types (e.g., lithium iron phosphate, ternary materials) and adjustable dimensions for the pouch, prismatic, and cylindrical cells.

-

MES Connectivity

Seamlessly integrates with factory management systems (MES) for real-time data analytics, traceability, and reporting, supporting Industry 4.0 standards.

Why Choose KATOP Lithium Ion Battery Testing Equipment?

High efficiency

Our lithium ion battery testing equipment delivers industry-leading energy performance with 82% charging efficiency and 73% discharge efficiency, making it one of the most energy-efficient solutions available.

Energy Savings

Compared to conventional feedback-type devices, our solutions save up to 20% in energy consumption. This makes our lithium battery test equipment not only cost-effective but also environmentally responsible.

Safety Features

Safety is prioritized in every design. Our equipment includes 20+ advanced protection mechanisms, including power loss data protection, over-charge/over-discharge protection, over-current/under-current protection, capacity protection, and various voltage protection mechanisms, among others. This ensures that your li-ion battery testing equipment remains safe and reliable under all operating conditions.

Green Manufacturing

At KATOP, we integrate green design principles into every iteration of our lithium battery testing equipment. Our solutions are designed to minimize energy waste and reduce emissions, fully aligning with national new energy policies and promoting sustainable manufacturing practices.

As a leader in lithium-ion battery testing equipment with 100% proprietary intellectual property, KATOP’s intelligent solutions are designed to meet the unique demands of the lithium battery production industry. With a deep understanding of industry processes, we accelerate the optimization of lithium battery testing equipment performance and are dedicated to expanding our global partnerships, offering our innovative technology to markets worldwide.

Join us in advancing the future of battery technology with our high-performance, energy-efficient formation/capacity testing equipment.