-

Against the Background of "Dual Carbon"

The rapid growth of the new energy vehicle industry and the expanding battery application scenarios have increased demand for innovation in lithium battery production technology, product quality improvement, and cost reduction. Upgrading lithium battery production lines to eliminate technical bottlenecks and extend equipment life cycles with minimal investment has become an optimal choice for customers. Li-ion battery production line upgrades can further improve production and management efficiency, enhance supply stability and sustainability, and promote the long-term development of enterprises.

-

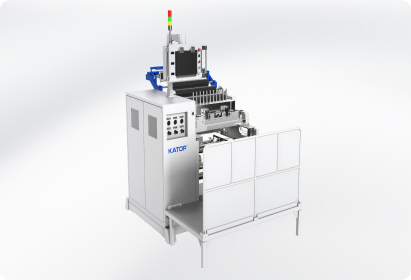

Achieve New Production Goals Cost-effectively

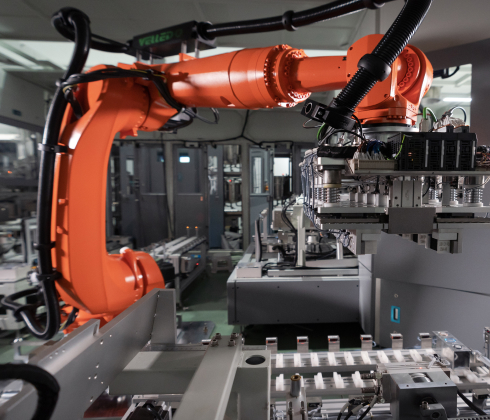

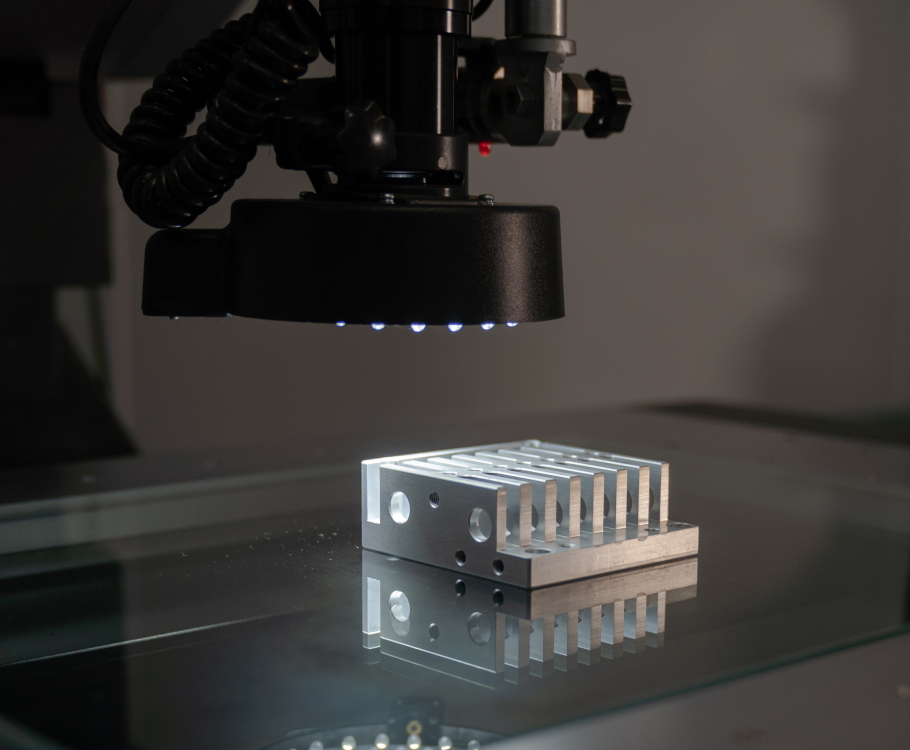

As a leading technical expert in the coating industry, KATOP brings extensive expertise and experience, fully integrating this knowledge into our lithium battery production line solutions. Our advanced equipment, such as separator coaters, gravure primer coaters, single-deck coaters, and double-deck coaters, provides a deep understanding of every aspect of the upgrade process and battery production line technology. As trusted lithium-ion battery production line suppliers, we always deliver customized solutions tailored to your specific targets, maximizing the performance and efficiency of your lithium battery production line equipment.

Upgrading your lithium battery production line doesn’t have to involve significant investments. With a small to medium-sized investment, we can help eliminate production bottlenecks and overcome previous process design limitations. Key upgrade modules include design engineering, new components, reconstruction, upgrading, process control, efficient commissioning, and after-sales service. By upgrading your existing machines instead of purchasing new ones, you can significantly extend the lifespan of your battery production line.

Our professional upgrade team specializes in full-system and component-level upgrades for KATOP coaters, and we also offer partial upgrades for coating equipment from other brands at home and abroad. Whether it's the unwinder, coating system, drying, traction, rewinder, or feeding system, we provide effective, customized solutions for your lithium-ion battery production line.

Additionally, we offer comprehensive dismantling, installation, and commissioning services (for KATOP equipment only), making equipment relocation or functional module transfers smooth and efficient. Our upgrades focus on enhancing coating quality, production efficiency, process control, and environmental sustainability. By improving key aspects like alignment correction, tension control, coating gap precision, drying efficiency, energy saving, and environmental protection, we maximize customer satisfaction and support the sustainable growth of your automotive battery production line.

Your Partner for Li-lon Battery Production Line Upgrades

As a leading China lithium-ion battery production line manufacturer with 100% independent intellectual property rights, we understand the critical demands of modern battery production line factories. Our solutions are designed to meet the highest standards of quality and performance, ensuring that your production lines remain competitive and efficient in an ever-evolving market.

-

01

Encountering process bottlenecks and cannot meeting customer needs

-

02

With poor equipment safety, casualties may easily occur

-

03

The equipment structure is too old and the energy consumption of raw materials is high

-

04

The overall automation degree is low, resulting in low efficiency and quality

-

05

Due to insufficient environmental considerations, pollution can easily happen

-

06

Frequent equipment failures increase economic cost

-

01

Improved production efficiency and quality can meet production requirements

-

02

The safety structure is more complete to eliminate production safety hazards

-

03

Fully realizing energy saving and consumption reduction, and achieving low energy loss of raw materials

-

04

The environmental protection system is upgraded and the working conditions for employees are improved

-

05

Equipment performance is better and can adapt to product upgrading

-

06

The equipment is highly intelligent and is easy and convenient for employees to operate