KATOP with upstream and downstream enterprises and a variety of innovative technologies as the carrier to build a test center, as an experimental test site, new technology, new materials test platform, equipped with a variety of types of verification equipment, a variety of different working conditions of the environment experiment scene (conventional atmospheric environment, glove box operating environment, clean workshop), We provide you with dry electrode powder treatment, electrode molding verification, new coating verification and slurry testing services. Among them, we have carried out thousands of experiments in the field of hydrogen energy, photovoltaic, fuel cells and other new energy, to provide you with more assistance until the production is successful.

-

Provide a variety of innovative process route experimental verification

-

According to the raw materials and needs provided by customers, assist customers to complete on-site verification

-

Provide a certain diaphragm, pole plate replacement processing, can be used as the end user sampling

-

Provide slurry, pole chip performance testing services

-

To provide new technology and new materials of intelligent equipment customized solutions

-

Cooperate with a number of well-known material factories for new material verification services

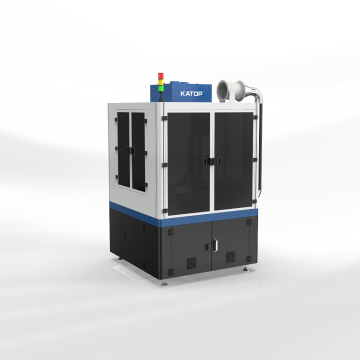

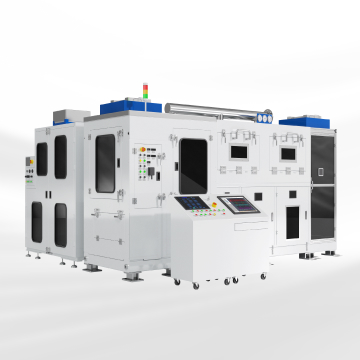

Experimental Equipment

Our Key Strengths in Battery Testing Services

KATOP’s Testing Center is transforming from a single validation platform into a hub for new energy technology incubation. Through our global network and collaboration with industry, academia, and research institutions, we continuously empower our customers’ innovation and industry upgrades.