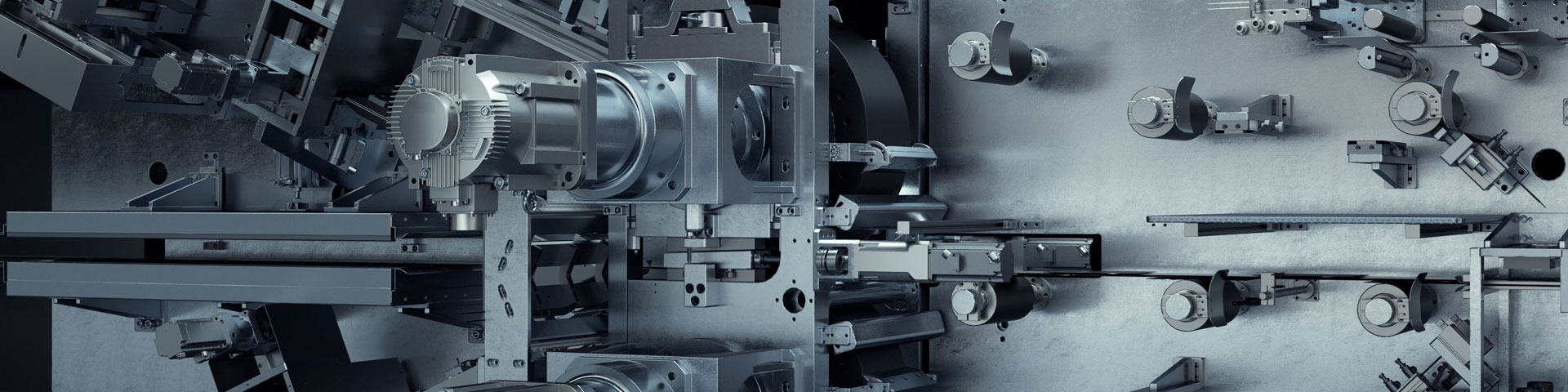

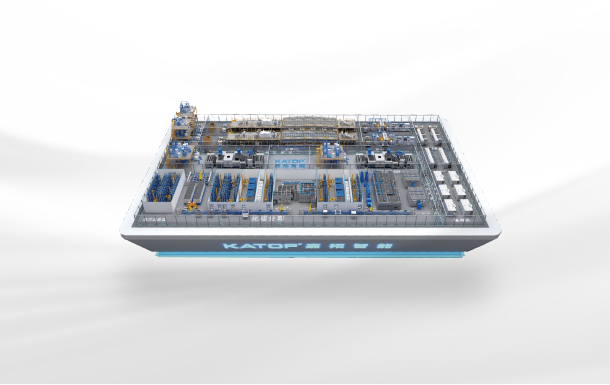

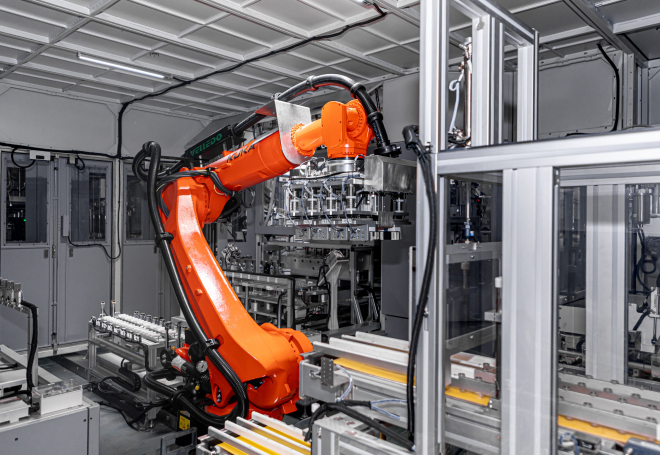

After more than ten years of R&D accumulation, KATOP has a deep understanding of raw material production, coating processing, automated production equipment, and energy storage equipment, as well as has expertise in the following core technical fields: automation, dry process, simulation and intelligent oven parameter prediction.

We are committed to seeking better solutions of new energy for the future and have conducted thousands of experiments in fields like hydrogen energy, photovoltaics and fuel cells. With nearly a thousand professional engineers and an organizational structure that can be flexibly adjusted according to customer needs, KATOP meets customers' requirements on high precision, high speed, informatization, safety and reliability of products, and works with customers on process development, prototype development and trial production.

Our Products and Services Include

-

Self-detection

-

Self-memory

-

Self-learning

Analyze information to generate actionable knowledge for guiding production activities, thereby achieving.

-

automatic equipment state self-tuning

-

edge detection (predictive maintenance)

-

-

Self-optimization

Utilize learned knowledge to form decision-making tendencies and automatically take actions based on optimal strategies.

-

closed-loop drying control

-

closed-loop dimensional control

-

closed-loop areal density control

-

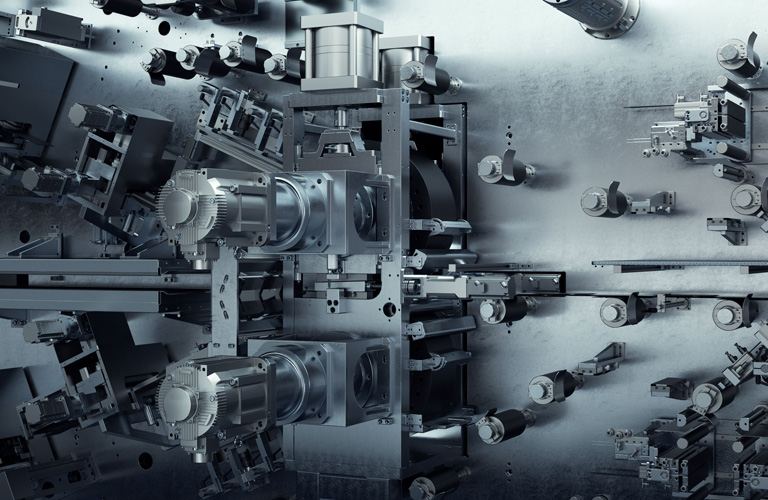

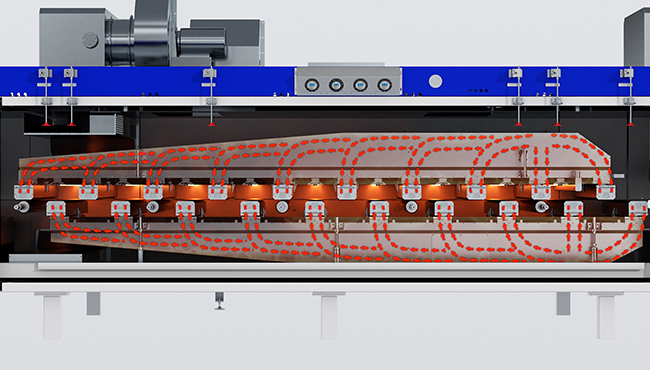

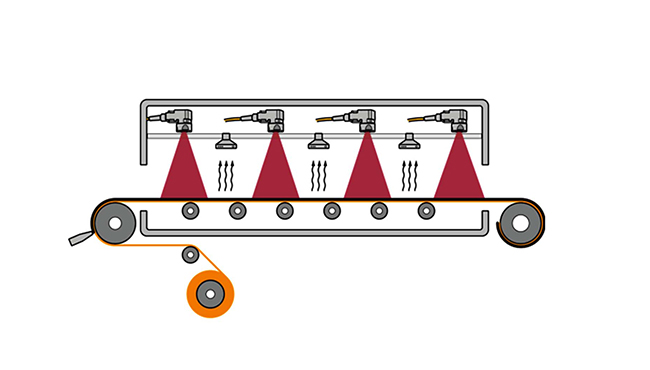

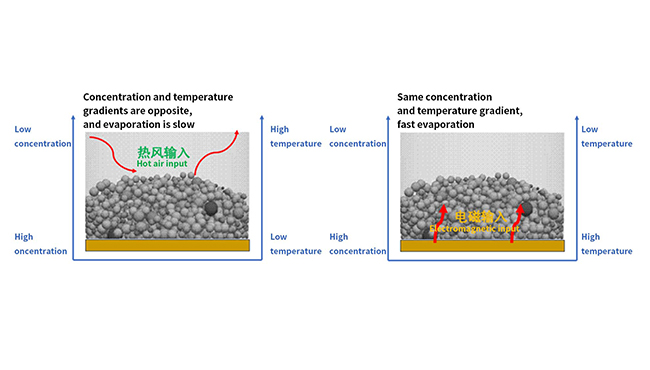

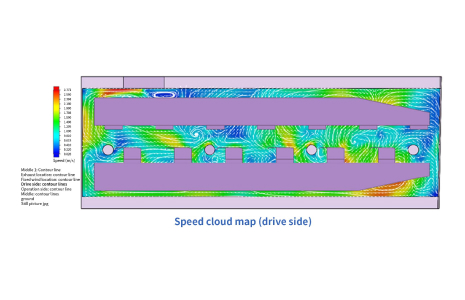

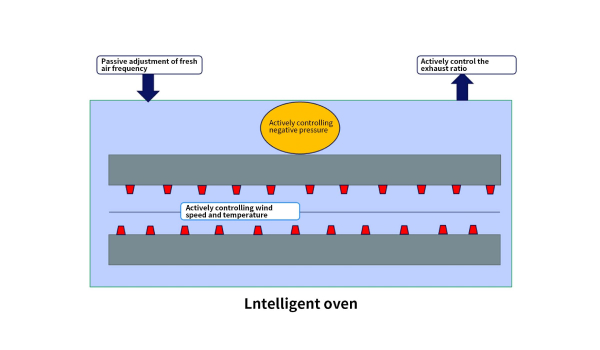

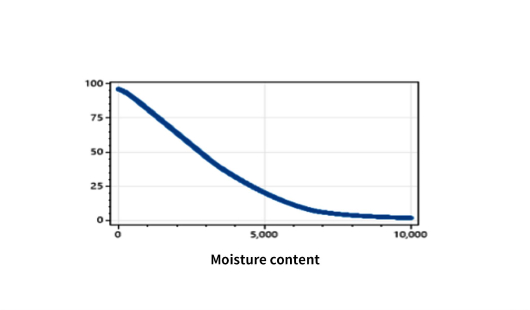

Through digital twin technology such as real-time collection, establishment of digital models, full data fusion, and self-learning intelligent prediction, we realize the visualization of important information such as slurry, coating, and equipment, and perform controls over automatic and manual switching, operation control, and drying parameters of each section of the dryer, to achieve the goals of efficient drying, always stable wind speed, and energy saving and emission reduction.

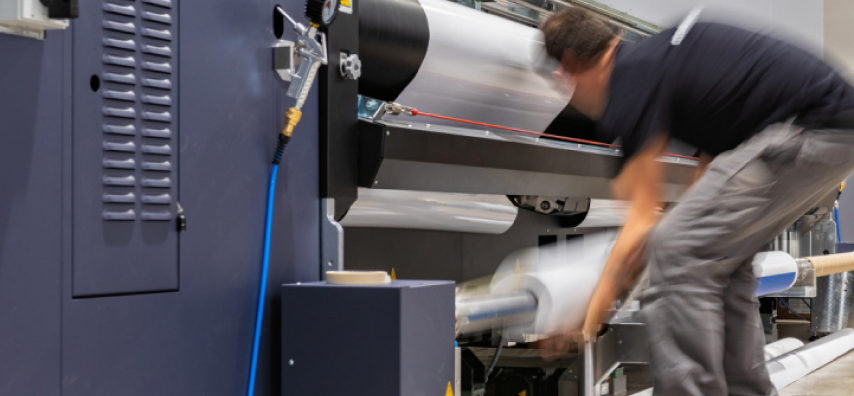

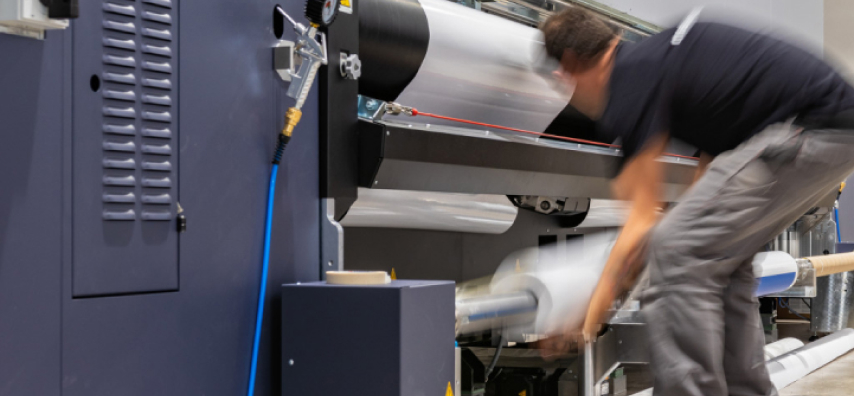

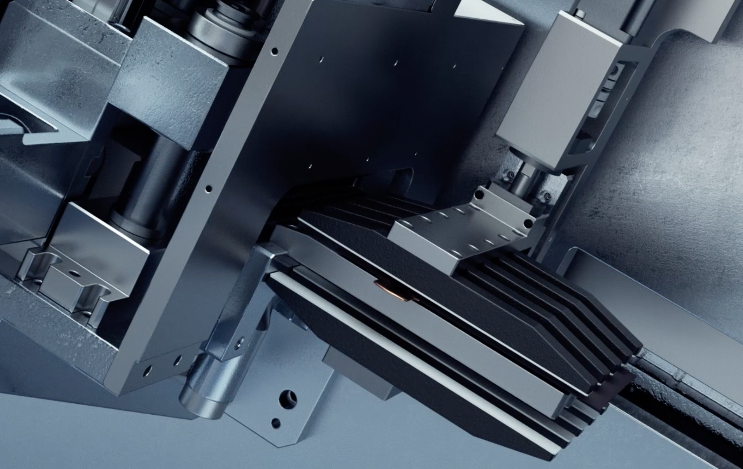

Highlights of Slitting Machines

-

servo motor-controlled cutting depth, with repeatability of ±0.005 mm

-

linear motor-driven blade gap control, with repeatability of ±0.002 mm

-

one-touch blade retraction

-

store and recall blade gap/cutting depth settings, and display rotational speed and linear velocity of blade drive motors.

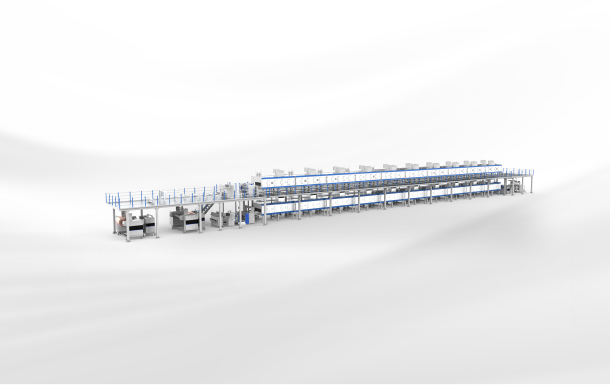

Highlights of Electrolyte Filling Machines

-

Revolutionary Settling

Technology -

Energy-Efficient

Positive Pressure Recovery -

Particle Control

-

Single-Port

Electrolyte Filling Cup -

Flexible Nailing

Technology

-

-

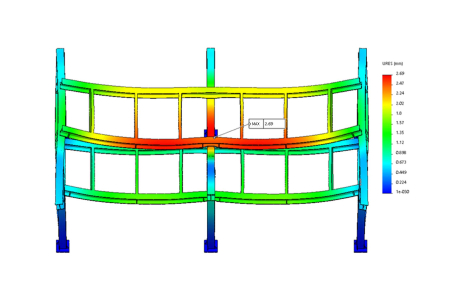

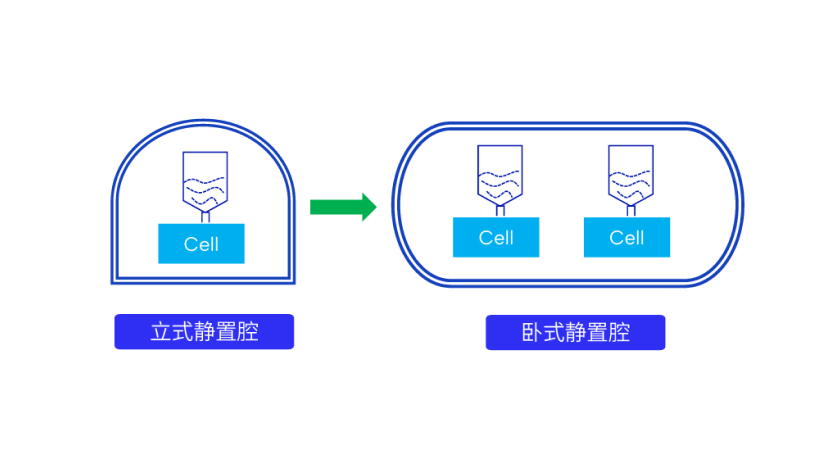

enhanced equipment stability: replaces vertical chambers (height-based) with horizontal chambers (length-based), eliminating heavy lifting and improving stability

-

optimized chamber capacity: extended horizontal chambers increase cell settling capacity per unit volume, boosting production density per square meter

-

cost reduction: compared to vertical chambers, horizontal chambers achieve equivalent cell settling capacity at lower overall structural costs.

-

-

-

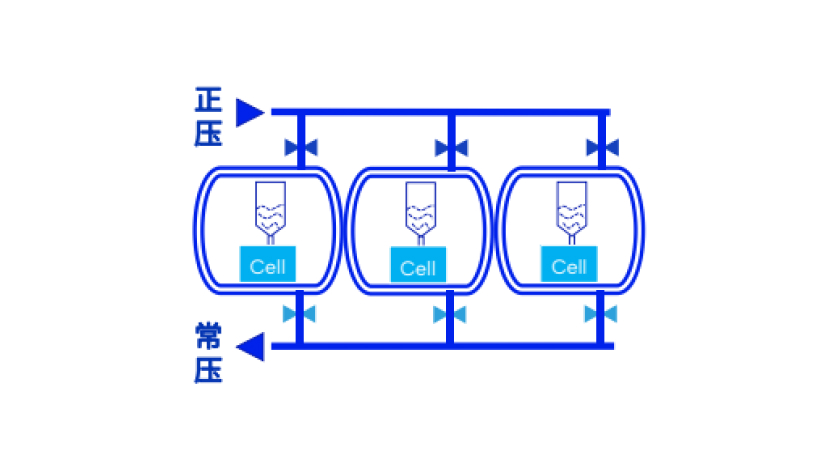

enhanced pressure cycling efficiency: the pressure balance method during chamber pressurization/depressurization enhances the pressure cycling efficiency while extending effective settling time

-

reduced depressurization noise: external exhaust initiates after 50% pressure balance, lowering initial exhaust pressure and noise emission

-

energy savings: the patented system recovers energy during depressurization, reducing about 50-70% positive pressure consumption.

-

-

-

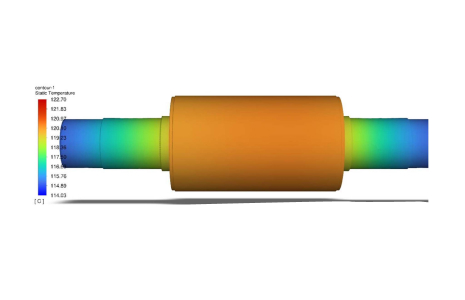

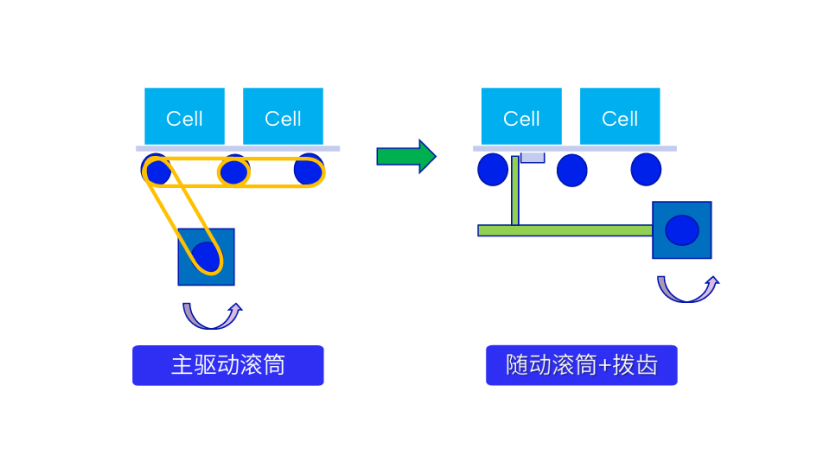

reduce particles and improve product quality: the follower roller + gear drive mechanism minimizes gear-driven pallet technology reduces friction between rollers and pallets, minimizing particle generation

-

improve maintenance accessibility: the optimized transmission design with simplified structure improves maintenance accessibility

-

reduce overall costs

-

-

-

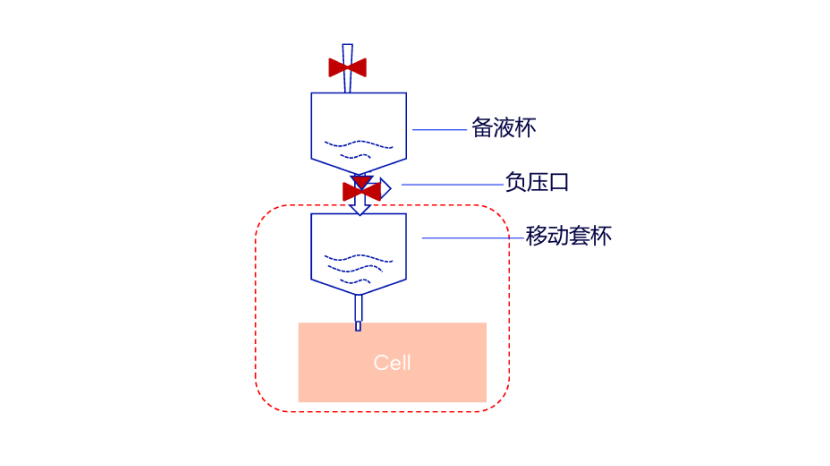

The single-port electrolyte filling cup replaces the dual-port design to reduce electrolyte adhesion on walls, minimizes crystallization risks, and enhance filling accuracy.

-

-

-

The flexible nailing technology improves nailing pass rates and reduces equipment failures.

-

Revolutionary Settling Technology

The entire machine is equipped with two sets of high-speed cutting and inserting mechanisms for both positive and negative electrodes. It can simultaneously cut and insert the electrodes, eliminating the bottleneck of alternating insertion of positive and negative electrodes and significantly improving the composite efficiency. Currently, this mechanism has applied for an invention patent.