-

LIB Equipment

-

- Single/Double Deck High-speed Coater

- Single Deck Extrusion Coater

- Separator Coater

- Double Deck Gravure Primer Coater

- Laboratory Coater

- Separator Slitter

- Electrode Slitter

- Integrated Calendering and Slitting Machine

- Doule-side Simultaneous Coater (Laser Drying)

- Laser Notching Machine

- Metal Die-Cutting Machine

-

-

Dry Process Electrode Production Solutions

-

Solid State Battery Production Equipment

-

Hydrogen Production Solutions

-

Coating Equipment for Perovskite Solar Cells

-

KATOP Excellence Center

-

Process equipment

-

More Services

-

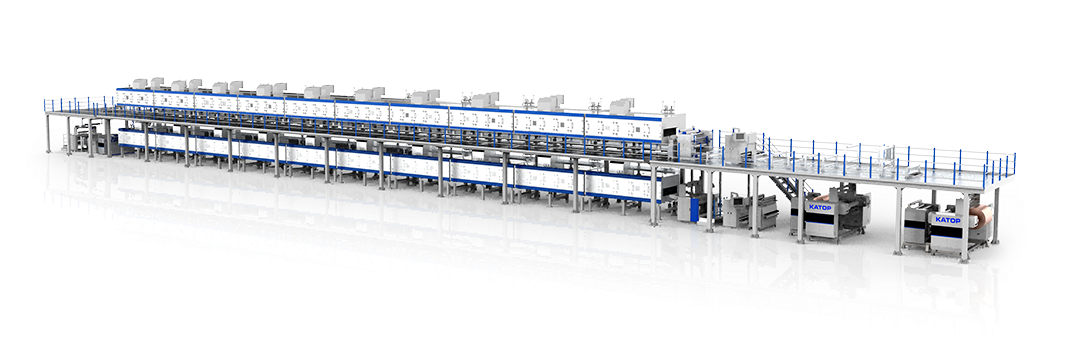

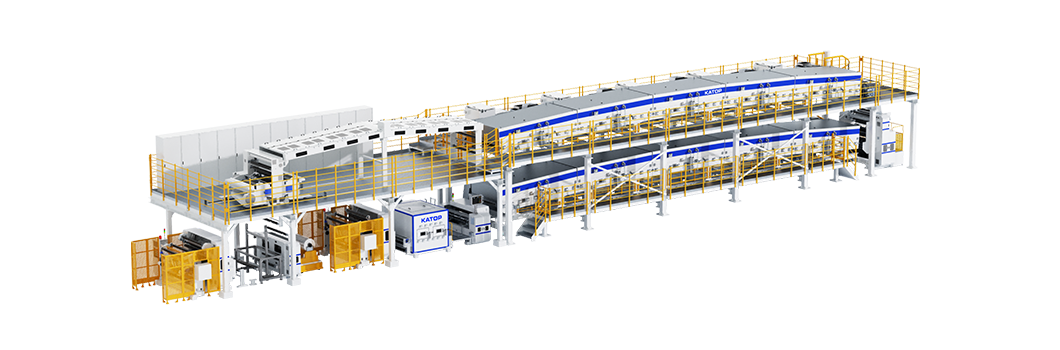

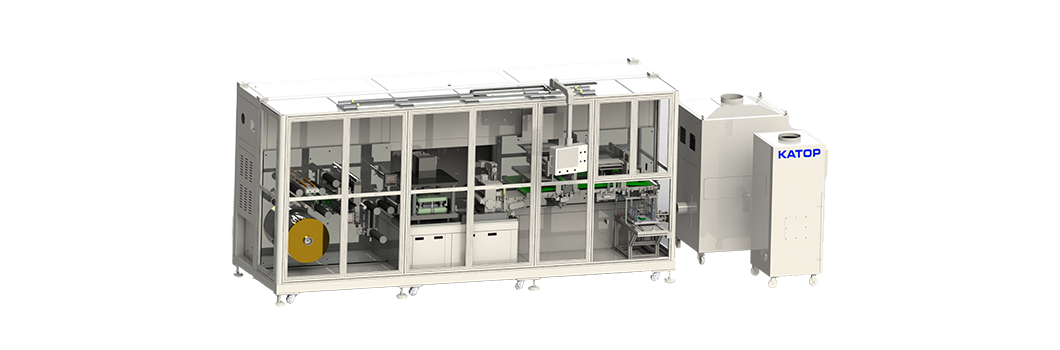

Single/Double Deck High-speed Coater

Designed for electrode production, this battery coating machine offers high-speed precision coating with a width of 1400mm and a minimum substrate thickness of 4.5μm. It features automatic thickness control, real-time monitoring, and efficient roll handling, ensuring high yield and operational efficiency.

-

Mechanical speed

MAX:150m/min

Roller width

MAX:1600mm

Speed accuracy

≤0.05%

-

Coating roller circle run-out

≤1.5μm(Laser measurement)

Tension

30~500N/±2N

Dryer temperature

MAX:150℃/±2℃

-

-

-

Coating method

Continuous slot die coating

Coating dimension accuracy

≤±0.3mm

Coating weight accuracy

±1%

-

Coating surface density

5~30mg/cm²

Mechanical speed

MAX:50m/min

Roller width

MAX:800mm

-

-

-

Coating method

Microgravure continuous coating / Rotating nozzle coating

Coating speed

CCS:MAX:150m/min

PCS:MAX:100m/minCoating width

MAX:1500mm

-

Rewinding tension

3~5N

Coating thickness accuracy

±0.3μm

Single side dry film thickness

0.5~10μm

-

-

Double Deck Gravure Primer Coater

This system is designed for coating functional underlayers on lithium-ion battery substrates, supporting continuous, intermittent, and zebra-striped coating modes, and is compatible with mainstream electrode coating machines.

-

Coating method

Gravure intermittent/ continuous coating

Coating width

MAX:1500mm

Coating speed

MAX:200m/min

-

Coating dimension accuracy

≤±0.3mm

Coating thickness accuracy

±0.3μm

Single side dry film thickness

1~10μm

-

-

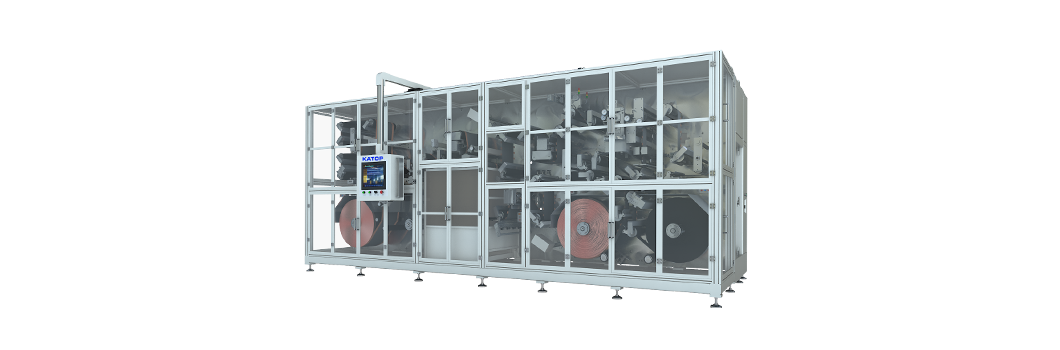

Laboratory Coater

The laboratory coater features a compact structure and supports various coating methods, making it an essential tool for coating research and development in lithium-ion battery production.

-

Coating width

MAX:380mm

Coating dimension accuracy

≤±0.3mm

Coating speed

MAX:15m/min

-

Coating weight accuracy

±1% / ±0.3μm

-

-

-

Slitting speed

MAX:300m/min

Qualification rate

≥99%

Utilization rate

≥98%

-

Maximum unwinding diameter

850mm

Minimum slitter width

35mm

Unwinding correction accuracy

±0.2mm

-

-

Electrode Slitter

This fully automatic slitting machine is tailored for Li-ion battery production, offering compatibility with both traditional round cutter and automatic cutter arrangement systems. Featuring an intuitive interface and easy operation, it ensures exceptional cutting precision and operational efficiency.

-

Slitting speed

MAX:100m/min

Qualification rate

≥99%

Utilization rate

≥98%

-

Maximum unwinding diameter

850mm

Minimum slitter width

35mm

Unwinding deviation correction accuracy

±0.2mm

-

-

-

Mechanical speed

MAX:120m/min

Calendering width

MAX:1400mm

Cold/hot roller

Optional

-

Roller specification

Φ900×1500mm

Roller no-load radial jump

≤±0.002mm

Thickness uniformity of electrode after rolling

≤±0.002mm

-

-

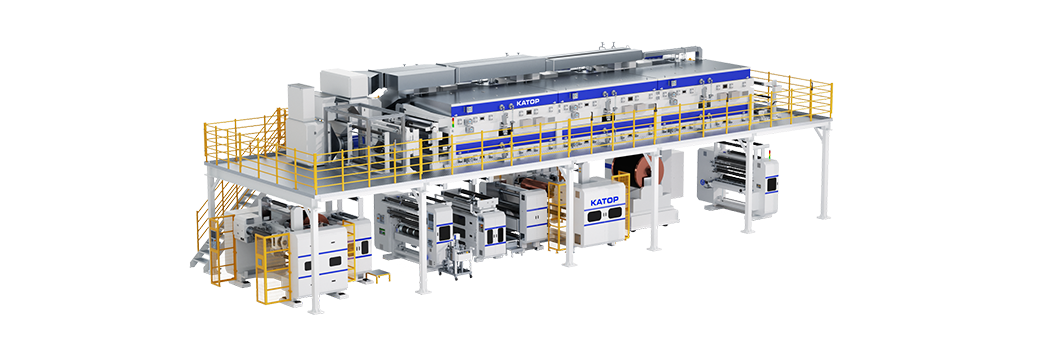

Doule-side Simultaneous Coater (Laser Drying)

The equipment is used for double-sided simultaneous coating process of wet electrode production line.

-

Output optical power density

120w/cm²

Operation speed

MAX:15m/min

Roller width

800mm

-

Coating width

700mm

Air supply/exhaust volume

2400 Nm³/h

Dryer temperature

MAX:150℃

-

-

Laser Notching Machine

Automated single/double-sided tab cutting and forming system for lithium battery electrode sheets with integrated slitting function; achieves consumable-free operation, high-speed processing, and stable cutting quality.

-

Electrode width range

200~600mm

Qualification rate

≥99.5%

Utilization rate

≥98%

-

Speed

MAX:120m/min

Electrode burr

≤10μm

Heat affected zone

≤80μm

-

-

Metal Die-Cutting Machine

This battery production equipment features automatic unwinding, splicing, EPC, and dust removal. Equipped with a precision tension control system, it ensures precise electrode tension management.

-

Electrode width range

W:100~200mm / H:150~300mm / Chamfer: ≥ R2

Qualification rate

≥99.5%

Utilization rate

≥98%

-

Capacity

PPM≥220(W=150mm)

Electrode dimension accuracy

±0.2mm

Electrode burr

≤10μm

-

High-Precision Electrode Making Equipment for Li-Ion Battery Production

In the lithium-ion battery manufacturing process, battery production equipment is categorized into front-end, mid-end, and back-end systems, each supported by a specialized battery production machine.

Front-end systems focus on electrode preparation, which includes mixing, coating, and slitting. This stage ensures the precise formation of electrodes, setting the foundation for battery performance.

Mid-end systems handle cell assembly, such as stacking, winding, and electrolyte filling, where the individual components come together to form a functional battery cell.

Back-end systems involve formation and testing processes to activate the cells and ensure they meet stringent quality standards

At KATOP, we deliver cutting-edge lithium-ion battery manufacturing machines tailored to optimize every step of this process.

Among the three stages of the manufacturing process, we specialize in front-end lithium-ion battery production equipment, which plays a critical role in electrode making. Our advanced machinery, including high-speed coating machines, slitting machines, and notching machines, ensures precision and efficiency at every step.

The coating process, an important part of electrode production, demands high accuracy. Our battery production machines achieve a coating dimension accuracy of less than 3 mm, eliminating surface imperfections that could compromise battery performance. As a pioneer in coating technology, KATOP offers a range of solutions, such as double-sided simultaneous high-speed coater, separator coater, and gravure primer coater, all designed to meet the highest industry standards.

Beyond front-end coating machines, we are constantly innovating to enhance the design and functionality of mid-end and back-end equipment. By integrating cutting-edge technologies, we deliver a comprehensive supply line of lithium-ion battery production equipment, ensuring seamless lithium-ion manufacturing processes from start to finish.

Why Choose KATOP Battery Production Equipment?

-

Innovative & Sustainable Solutions

KATOP integrates cutting-edge technologies like dry electrode coating and solvent-free processes, aligning with the global shift toward eco-friendly and high-energy-density battery production. Our equipment not only enhances production efficiency but also reduces environmental impact, making it a preferred choice for forward-thinking manufacturers.

-

Customizable for Every Production Scale

Whether you're running a lab, pilot line, or full-scale production, our lithium-ion battery production equipment is fully customizable. From adjustable machine speeds to tailored dimensions, we ensure our machines meet your specific requirements, helping you optimize costs and accelerate time-to-market.

-

Expert Team & Local Support

With a skilled professional team and exceptional service standards, KATOP has established itself as a trusted provider of battery production equipment. Our commitment to innovation, combined with comprehensive after-sales support, ensures seamless integration and long-term reliability for your production lines. Choose KATOP for precision, efficiency, and sustainability in lithium-ion battery production equipment. Let us help you build the future of energy storage.

Products Description

KATOP’s single/double deck high-speed coater is a facility that coats and dries the lithium-ion battery active material on aluminum and copper foils.

Key Features of Lithium Ion Battery Coating Machine

Our single/double deck high-speed coater is designed to meet the critical demands of modern lithium-ion battery manufacturers.

-

Smart Automation &

Precision ControlMES/PC/AGV integration enables seamless production line automation and real-time data tracking.

CCD-based size monitoring and auto-die cleaning minimize defects and downtime.

-

End-to-End Quality

AssuranceReal-time monitoring of surface density, temperature, NMP concentration, and moisture content.

CCD defect detection ensures only flawless electrodes proceed downstream.

-

Advanced Coating

FlexibilityDual chamber slot die enables double-layer coating in a single pass.

Large-wide substrate coating pre-slitting (one divides into two) boosts throughput by 30%.

-

Energy-Efficient Drying

SolutionsCustomizable airflow patterns and heating methods (steam, heat transfer oil, or infrared), featuring energy saving and high efficiency.

Explosion-proof design meets strict safety standards while reducing energy consumption by 15-20%.

-

Zero-Contamination

DesignCopper/zinc/nickel-free contact surfaces prevent electrode contamination.

FFU dust compartments maintain ISO-class production environments.

-

Built to Last, Easy to

MaintainPatented structure design, extended service life, and convenient maintenance.

Self-made machined parts guarantee quality control and rapid delivery.

Why Choose KATOP’s Lithium Ion Battery Coating Machine?

Faster ROI: High-speed coating (up to 100m/min) with 99.5% yield reduces waste.

Superior quality: Precision controls and advanced monitoring ensure defect-free electrodes.

Cost savings: Energy-efficient drying and minimal material waste lower operational costs.

Leading Lithium Ion Battery Coating

Machine Supplier

As a leading battery coating machine manufacturer, KATOP has driven innovation in coating technology for over 20 years, delivering precision-engineered solutions for lithium-ion battery production worldwide. With professional design quality and a commitment to technical excellence, we have accumulated extensive expertise in coating process engineering.

Our portfolio includes a full range of high-performance LIB Coating Machines:

-

Single/Double Deck High-speed Coater

-

Separator Coater

-

Double Deck Gravure Primer Coater

-

Laboratory Coater, and so on.

Trusted by over 150 battery manufacturers globally, we have deployed 4,500+ lithium-ion battery coating machines that operate reliably, making us a trusted battery coating machine supplier for the energy storage industry.

Whether you're upgrading existing lines or expanding production capacity, KATOP provides battery coating machines designed to boost yield, reduce waste, and accelerate your time-to-market.