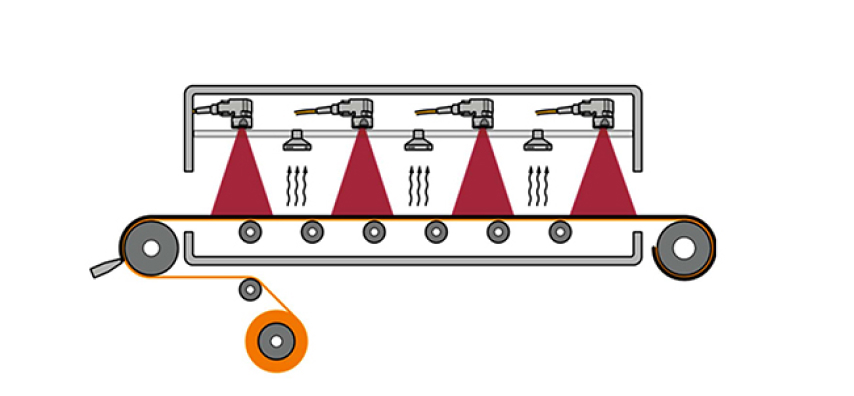

Infrared laser heating technology can slow down the temperature gradient in the depth direction, shorten the action time of capillary effect, fully alleviate the floating of adhesive, and delay the film forming time; And effectively avoid overheating of the dried area, weaken the capillary effect, and effectively increase the porosity. In the production process, the gentle temperature gradient control is realized, thereby reducing the internal stress and effectively reducing the risk of pole piece cracking.

sales center

-

+86 13622683953

-

Jiangsu KATOP Automation Co., Ltd

-

sales@katopauto.com