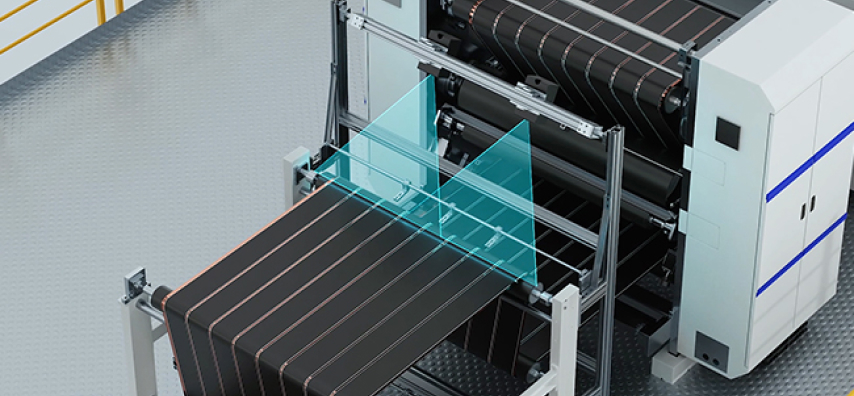

Flatbed Coating Machine (GW-level)

An industrial-grade coating solution specifically designed for GW-level perovskite production lines. It utilizes reliable precision coating technology and fully automated process control to achieve high uniformity and production stability for large-area thin films, thereby ensuring high yield in large-scale mass production.

Product Feature

-

Intelligent Automation

ntegrated with MES system, supporting remote recipe upload and download, combined with robotic automatic loading and transfer unloading system, enabling unattended workshop operation.

-

Stable Structural Foundation

Utilizes air-flotation guideways for transmission, ensuring smooth motion without mechanical friction, further reducing vibration interference and providing a reliable mechanical platform for high-uniformity coating.

-

Ultra-precision Vibration Control

Built-in professional vibration isolation mechanism ensures coating thickness uniformity.

-

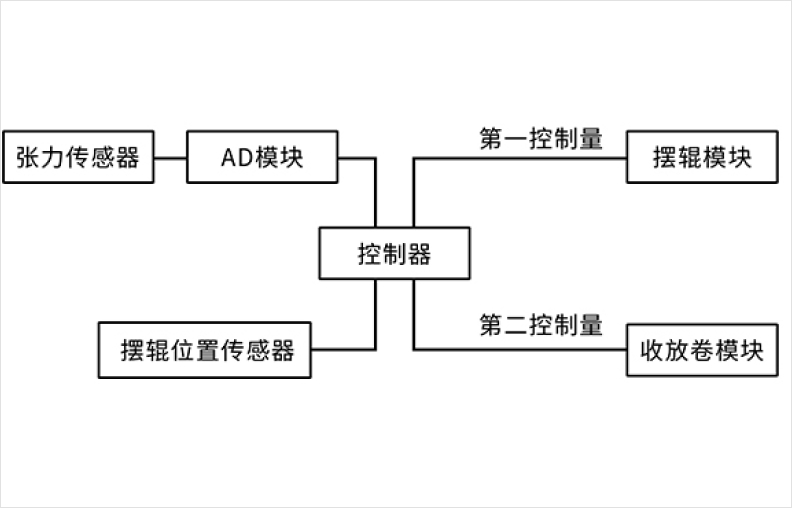

Self-developed Precision Liquid Supply System

Equipped with a self-developed high-precision liquid supply pump, with flow control resolution better than 0.1 μl/s, ensuring stability and reliability.

-

Fully Automatic Die Head Calibration and Adjustment

Fully automatic calibration and adjustment of the slot-die coating head, with an accuracy of up to ±1 μm, ensuring the precision of the coating head and the consistency of slurry output from the source.

-

Fully Automatic Bubble Removal

Automatically detects and removes bubbles, and features a pre-coating mechanism design to eliminate coating defects caused by bubbles.

-

Intelligent Protection for Die Lip Foreign Objects

Capable of detecting micro contaminants ≥50 μm, providing active alerts to protect the core die lip.

-

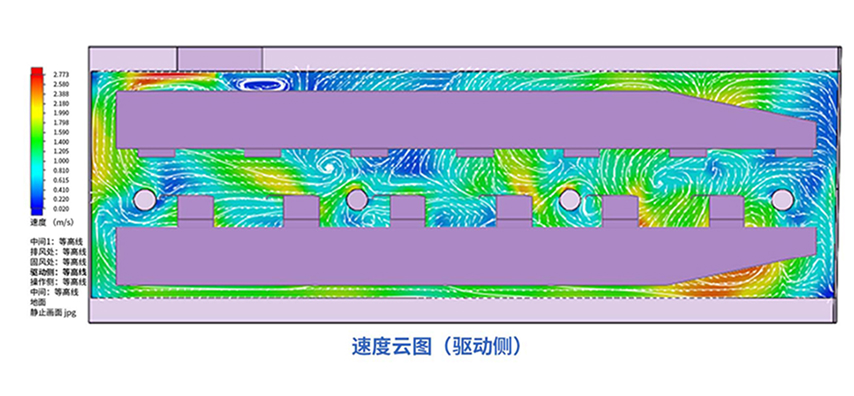

Class 100 Clean Coating Environment

Integrated FFU system maintains a Class 100 cleanliness standard in the core coating area, with self-cleaning functionality for the die lip.

Product Model

-

Total Weight

16T

Coating Method

Slot-die Coating

Substrate size

1200Mmx2400mm (Compatible with smaller sizes)

Coating Width

1200mm (Customizable)

Coating Uniformity

≤5%@(300~600nm)

Compatible Slurry Viscosity 1~70cp

Cycle time

75s@60mm/s

sales center

-

+86 13622683953

-

Jiangsu KATOP Automation Co., Ltd

-

sales@katopauto.com

sales center

-

+86 13622683953

-

Jiangsu KATOP Automation Co., Ltd

-

sales@katopauto.com