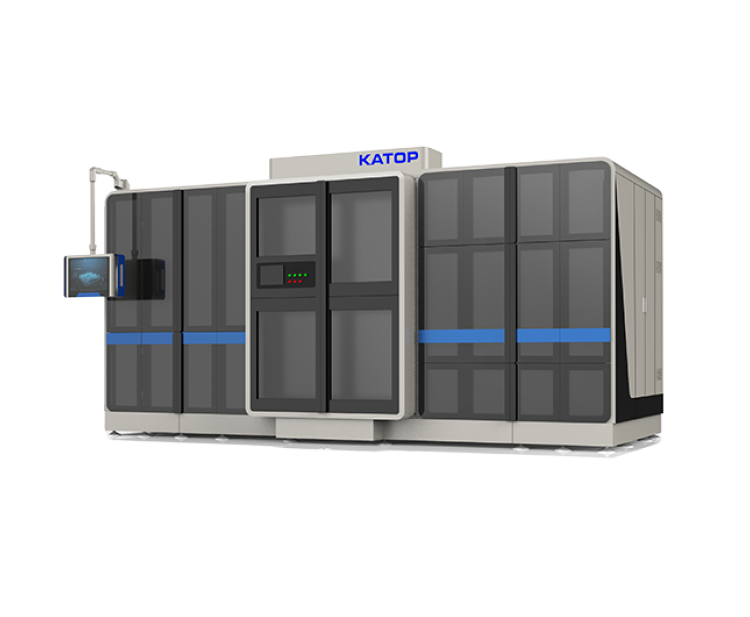

Winder

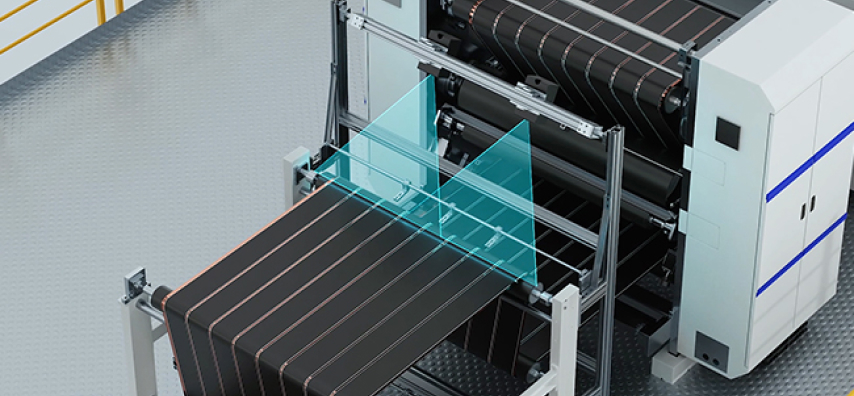

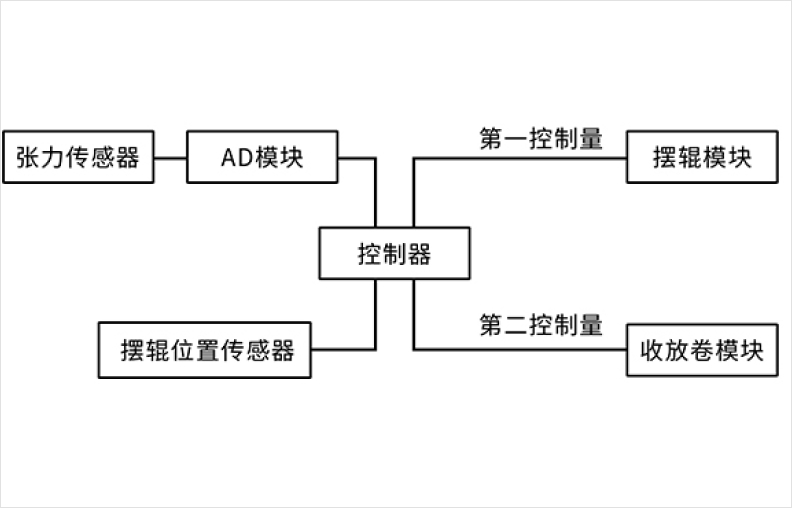

This equipment is mainly used for automatic winding of square EV bare cells. Main functions: active unwinding, automatic rewinding, servo closed-loop low tension measurement and control system, EPC deviation correction, snake deviation correction, feeding clamping linear deviation correction, FFU and dust removal system, pole piece sticking protective glue, automatic rejection of incoming materials, tab folding detection, pole piece defect online detection, CCD alignment online detection, battery cell clamping and blanking, preloading and cold pressing, code scanning weighing and data tracing system.

Product Feature

-

We have the patent of independent polygon winding needle, which can realize circular winding.

-

It has a multi-stage high-precision rectification system, and accurately detects the alignment between the two sides through CCD imaging, which can better control the alignment between the pole piece and the diaphragm, reduce the overhang defects and improve the yield of the finished equipment.

Product Model

-

Parameters Values Dimensions(L*W*H) 6200*2600*2610mm Yield Rate ≥99% Operational Rate ≥98% Winding speed ≥3.5m/s Tension fluctuation ≤±5% 极片 ≤±2% 隔膜 PPM PPM≥10 (设计产能PPM≥20) Alignment control ≤±0.3mm

sales center

-

+86 13622683953

-

Jiangsu KATOP Automation Co., Ltd

-

sales@katopauto.com

sales center

-

+86 13622683953

-

Jiangsu KATOP Automation Co., Ltd

-

sales@katopauto.com