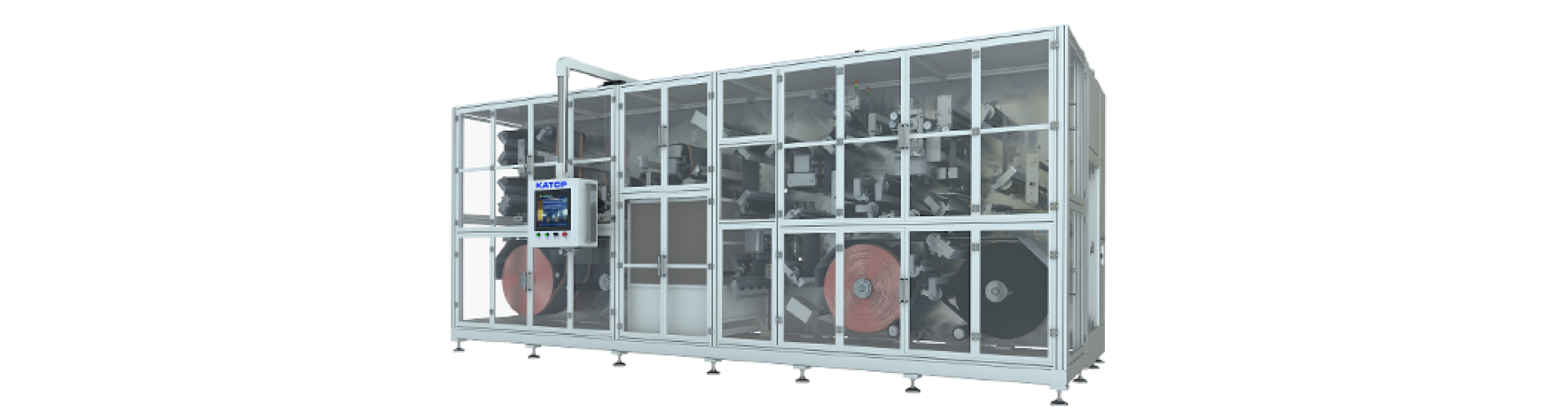

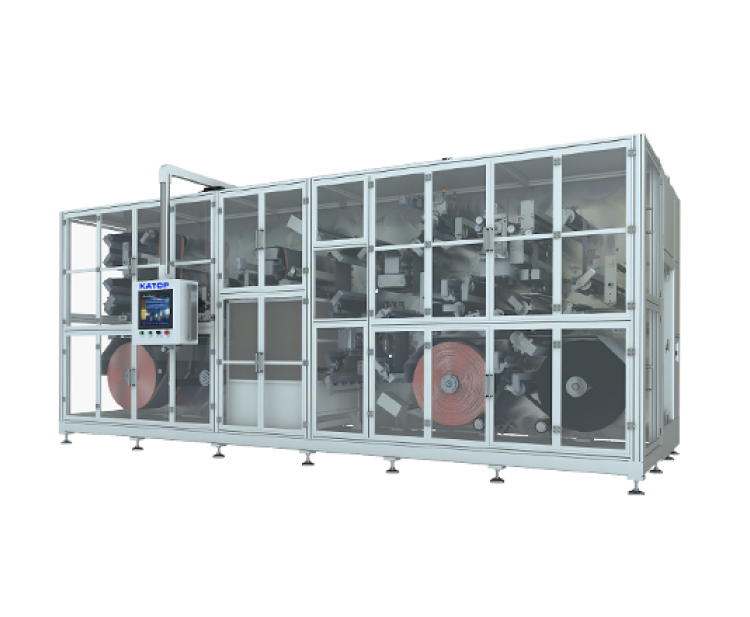

Laser Notching Machine

Automated single/double-sided tab cutting and forming system for lithium battery electrode sheets with integrated slitting function; achieves consumable-free operation, high-speed processing, and stable cutting quality.

Product Feature

-

Automated single/double-sided tab cutting and forming system for lithium battery electrode sheets with integrated slitting function; achieves consumable-free operation, high-speed processing, and stable cutting quality.

-

Automatically adjusts tab spacing and enables variable tab cutting based on cell design requirements. Capable of producing tabs with diverse spacing and geometries, offering high design flexibility for various battery types and specifications.

-

The cutting process integrates: Dust removal for both sheet-path and rewinding sections Dual inspection systems: CCD imaging + photoelectric sensors Plasma air knife cleaning technology

-

Equipped with MARK hole cutting capability (for winding process alignment)

-

Equipped with: CCD vision inspection for defect detection Electrode buffer system to optimize material usage Automatic position recalibration for defective incoming material, minimizing electrode waste.

-

Integrated dust removal and automatic scrap edge compression/collection system to prevent secondary contamination.

Product Model

-

Coated Product Specifications Value Electrode Width Range 200-600mm Yield Rate ≥99.5% Operational Availability ≥98% Speed MAX:120m/min Electrode Burr ≤10μm Heat Affected Zone (HAZ) ≤80μm Cutting Dimensional Accuracy ±0.2mm

sales center

-

+86 13622683953

-

Jiangsu KATOP Automation Co., Ltd

-

sales@katopauto.com