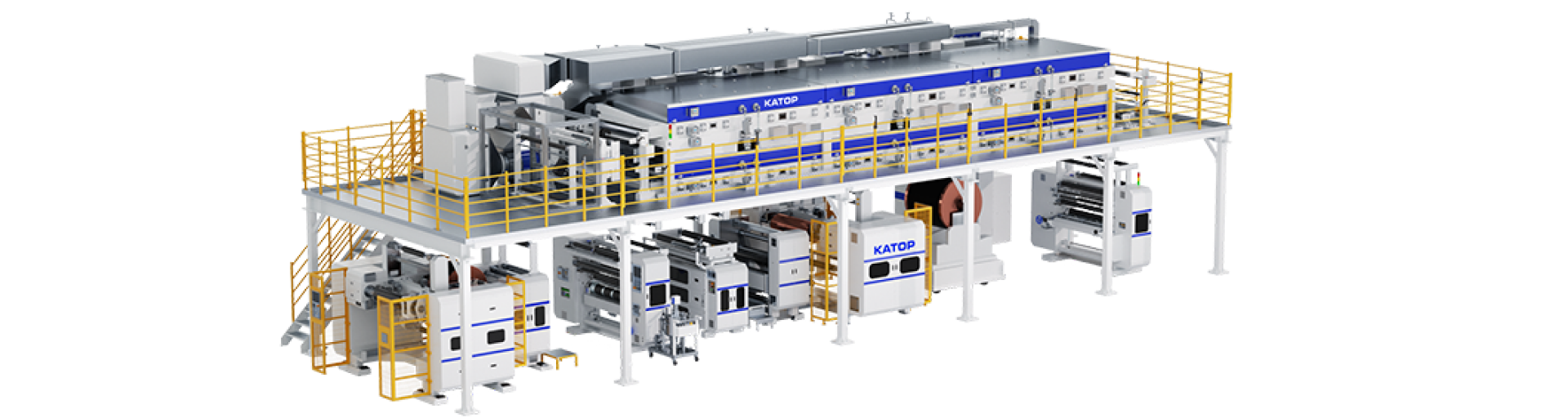

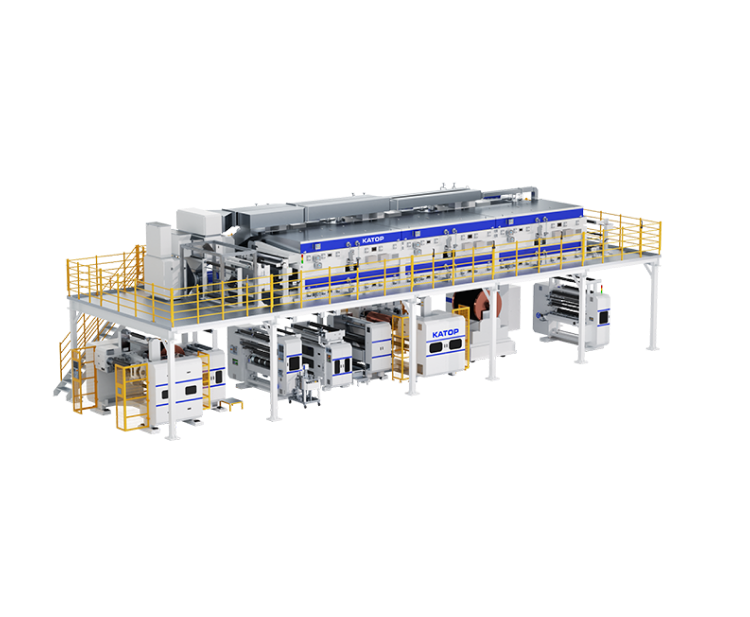

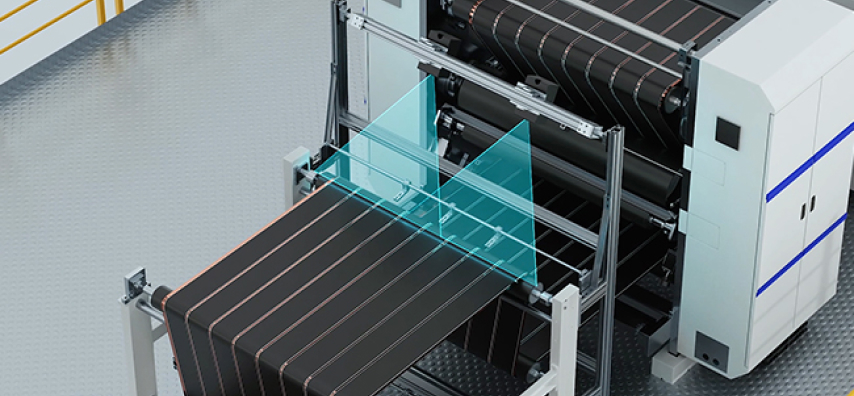

Double Deck Gravure Primer Coater

Product Feature

-

Optional FFU (Fan Filter Unit) clean booth configuration

-

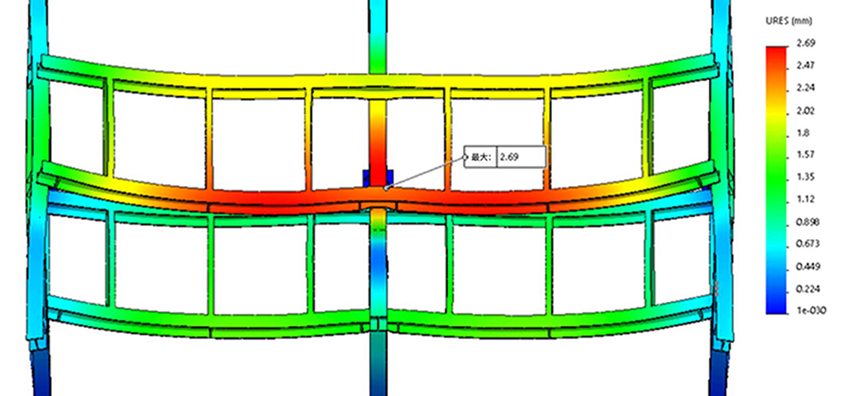

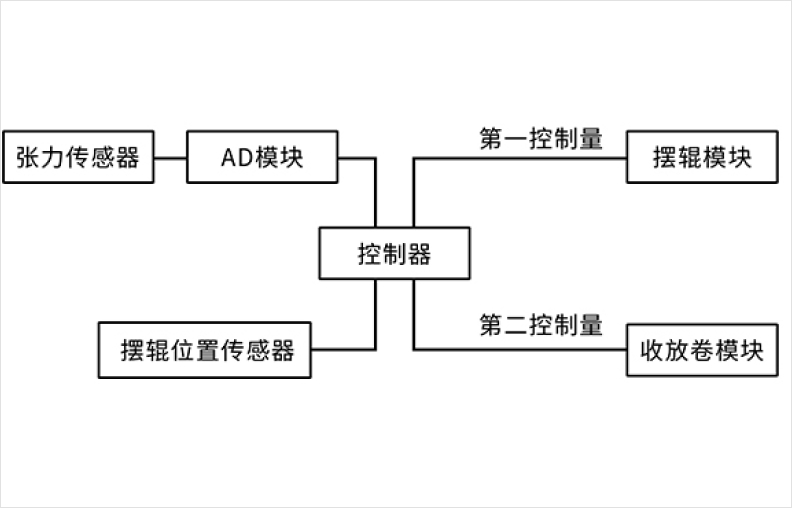

Closed-loop control for front/back coating stagger (machine/cross direction)

-

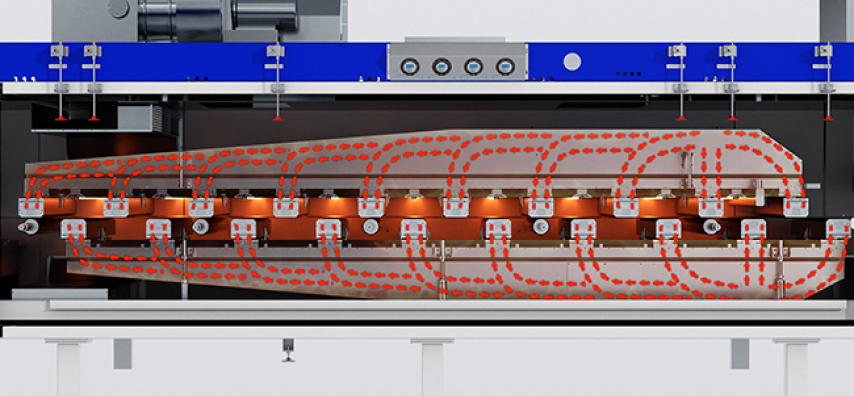

andem double-side coating in single pass

-

Compact design with customizable layouts per client requirements

-

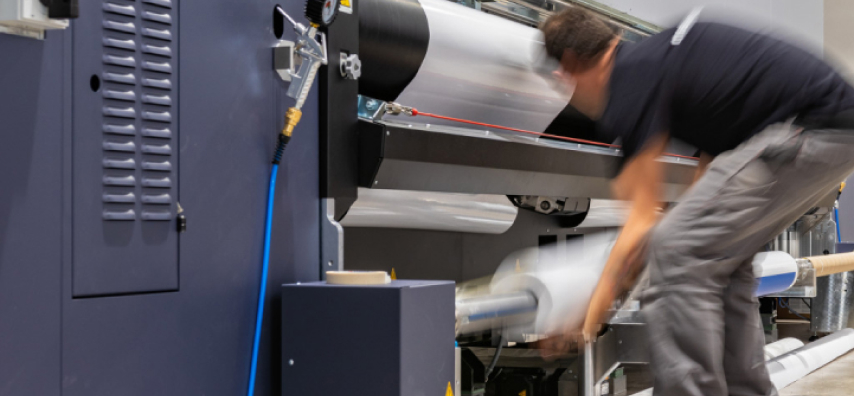

Interchangeable engraved roll patterns for variable coating length/width

-

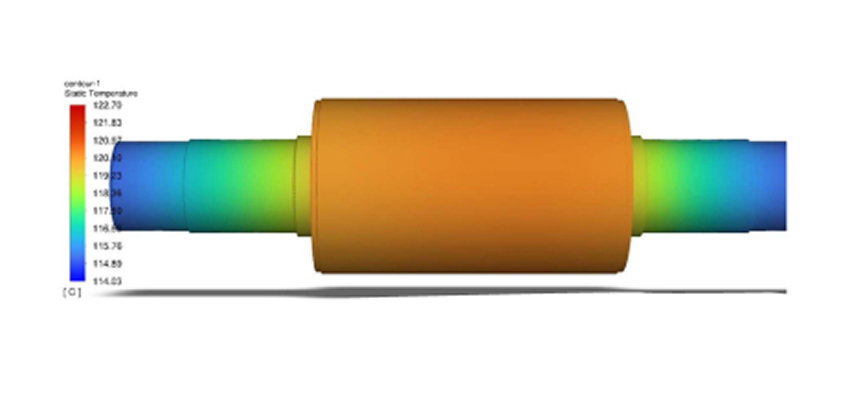

Gravure roll diameter range: Φ200-650mm, compatible with mainstream primer coating processes

-

Designed for functional underlayer coating on battery substrates, supporting continuous/intermittent/zebra modes, integrated with electrode coaters

Product Model

-

Model Dimensions Substrate Width Drying Zones Heating Methods KC-G-800-16.16-A.A 24000*4500*4000 700 16 Electric / Thermal Oil / Steam KC-G-1000-16.16-A.A 24000*4800*4000 850 16 Electric / Thermal Oil / Steam KC-G-1200-16.16-A.A 25000*5200*4000 1050 16 Electric / Thermal Oil / Steam KC-G-1400-16.16-A.A 25000*5700*5000 1250 16 Electric / Thermal Oil / Steam KC-G-1600-16.16-A.A 25000*6300*5000 1450 16 Electric / Thermal Oil / Steam -

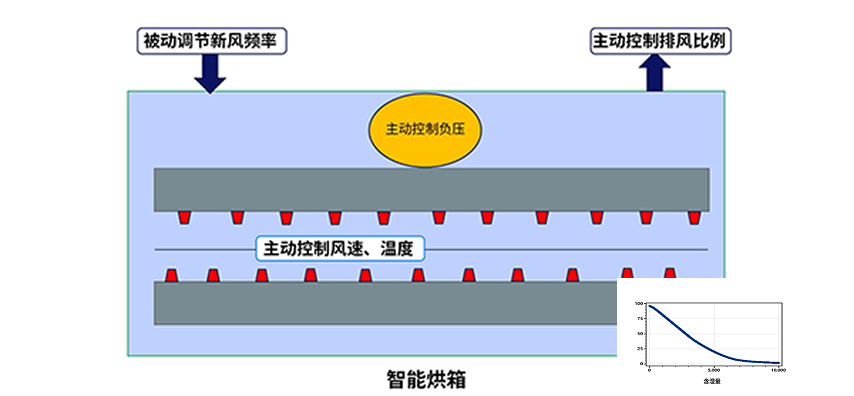

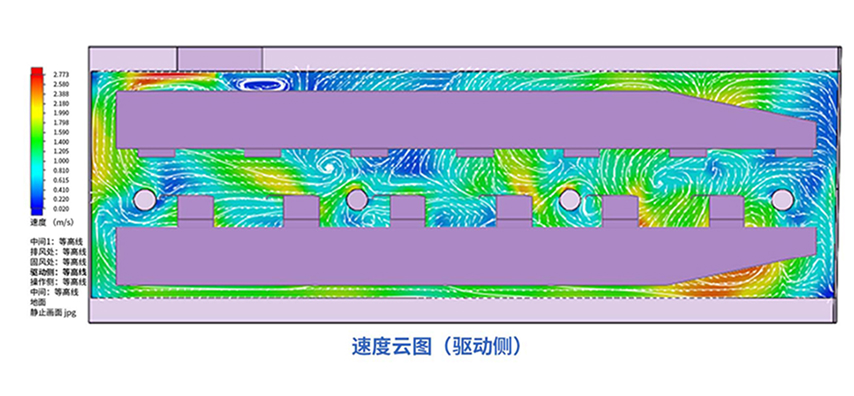

Coating Product Specifications Value Coating Method Gravure intermittent/continuous coating Coating Width MAX:1400mm Coating Speed MAX:200m/min Coating Dimension Accuracy ≤±0.3mm Coating Thickness Accuracy ±0.3μm Dry Film Thickness (Single Side) 0.3-2μm、1-10μm Substrate Thickness AL 8-20μm/Cu 4.5-20μm Roll Size/Weight MAX: Φ800mm/1000kg Roll Face Width MAX:1600mm Tension Range/Accuracy 30-300N/40-500N Oven Temperature MAX:160℃±3℃

sales center

-

+86 13622683953

-

Jiangsu KATOP Automation Co., Ltd

-

sales@katopauto.com

sales center

-

+86 13622683953

-

Jiangsu KATOP Automation Co., Ltd

-

sales@katopauto.com