Laboratory Coater

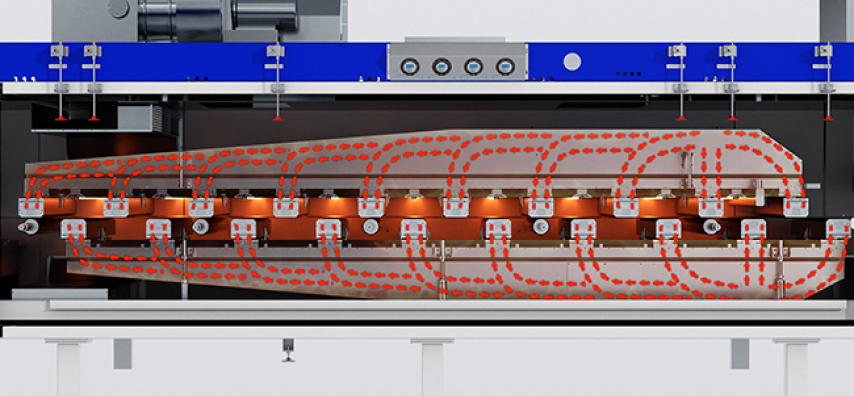

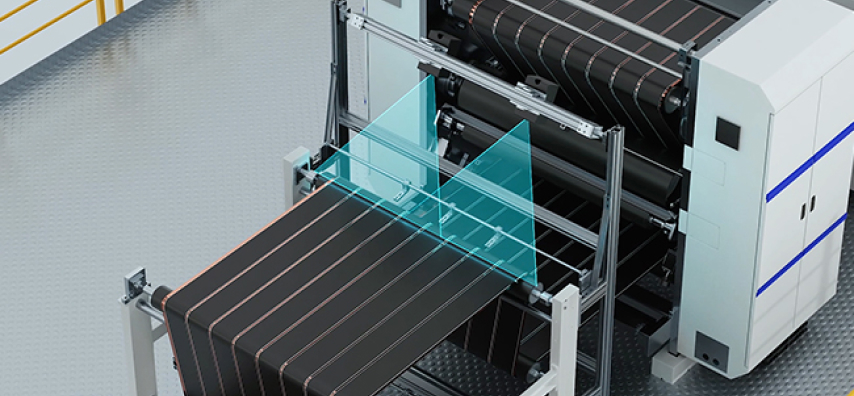

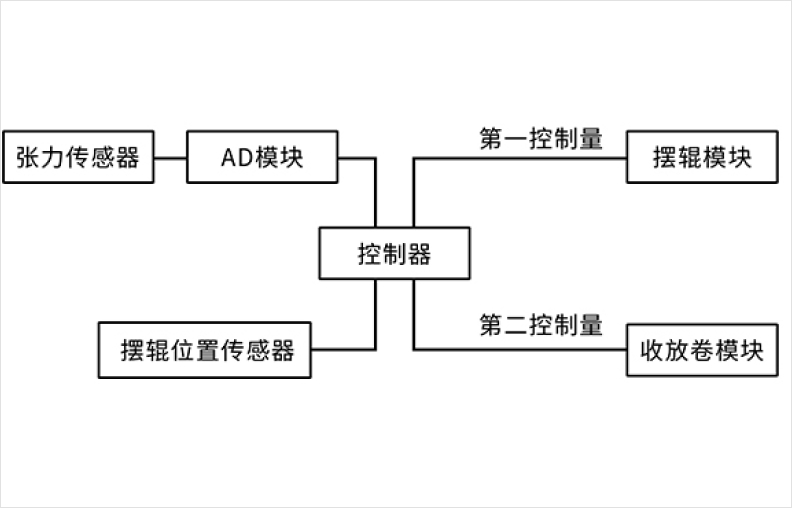

The laboratory coater features a compact structure and versatile coating methods, making it widely suitable for coating research applications.

Product Feature

-

The laboratory coater features a compact structure and versatile coating methods, making it widely suitable for coating research applications.

-

Features slurry-saving design, intuitive operation, and enhanced safety protocols

Product Model

-

Equipment Type Model Dimensions Compatible Substrate Width Drying Zones Heating Method Lab Slot-Die Coater KC-SD-480-6-M.M 13000*2500*2500 400 6 Electric Lab Transfer Coater KC-M-480-6-M.M 8500*2300*2300 400 6 Electric Multi-Function Lab Coater KC-LC-400-4.5-M.M 6000*2500*2500 300 4.5 Electric -

Parameter Value Coating Method Transfer Coating Coating Width MAX:380mm Coating Speed MAX:3m/min Weight Accuracy ±1.5% Coating Dimension Accuracy ≤±0.5mm Areal Density 5-30mg/cm² Roll Size/Weight MAX:Φ250mm/150kg -

Parameter Value Coating Method Slot-die continuous/intermittent coating / Profile coating Coating Width MAX:380mm Coating Speed MAX:3m/min Coating Dimension Accuracy ≤±0.3mm Coating Weight Accuracy ±1.0% Areal Density 5-30mg/cm² Substrate Thickness AL 9-20μm/Cu 4.5-20μm Roll Size/Weight MAX:Φ600mm/500kg

sales center

-

+86 13622683953

-

Jiangsu KATOP Automation Co., Ltd

-

sales@katopauto.com

sales center

-

+86 13622683953

-

Jiangsu KATOP Automation Co., Ltd

-

sales@katopauto.com