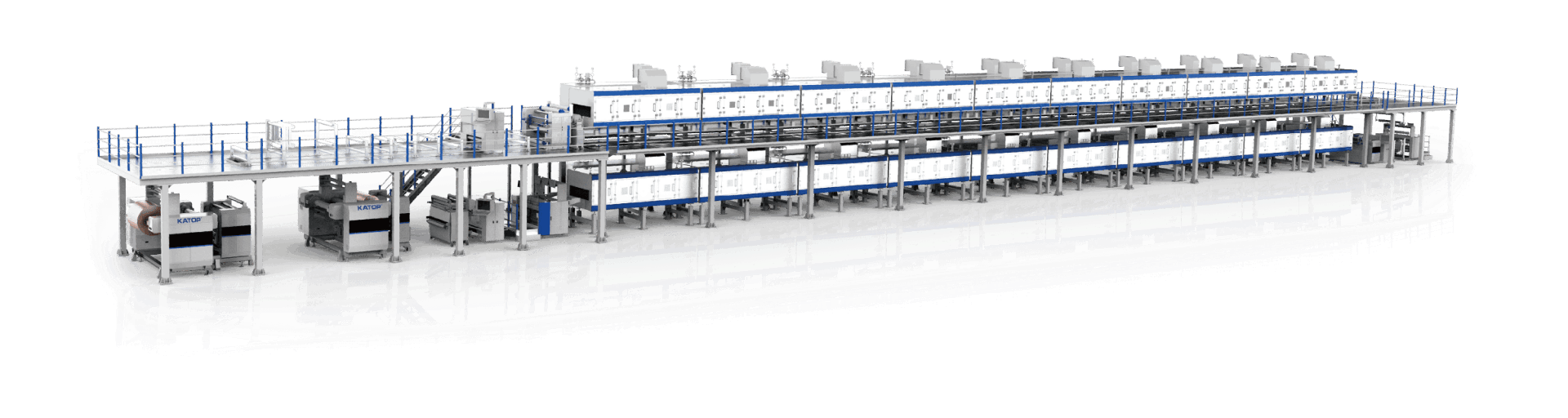

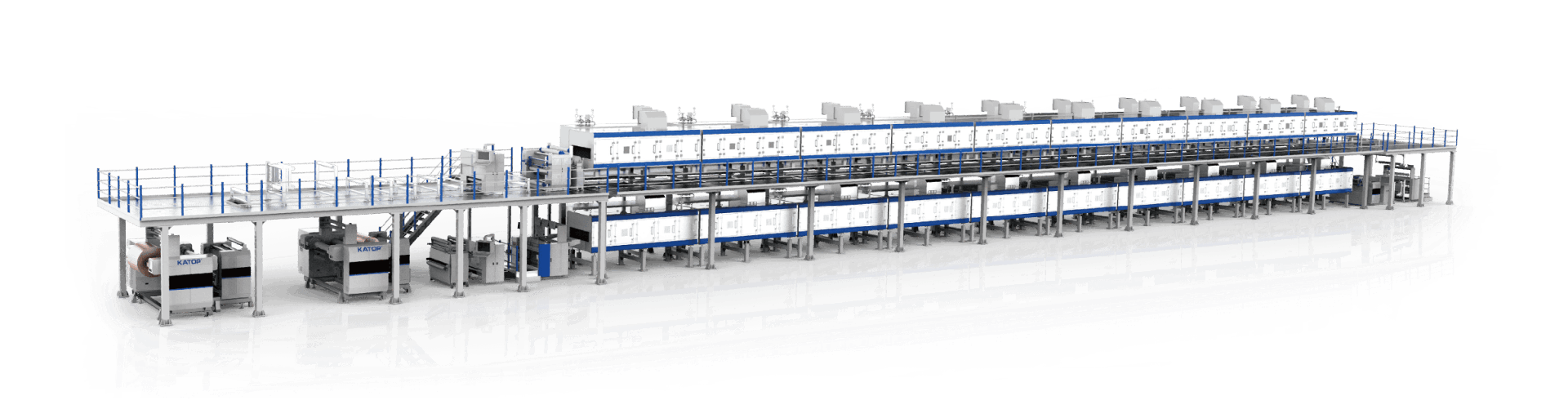

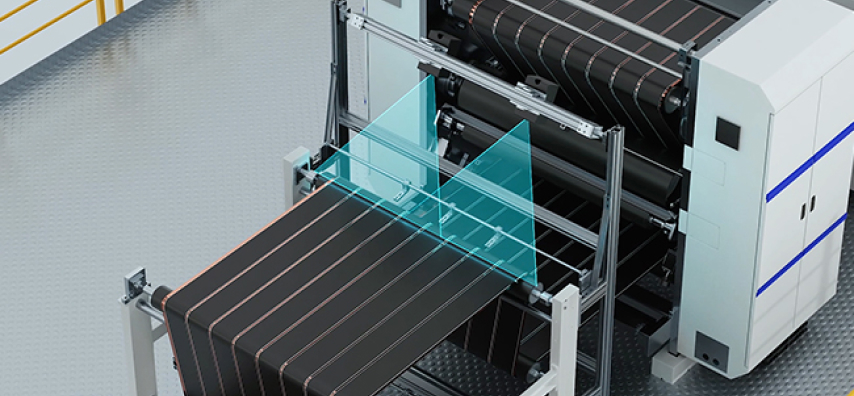

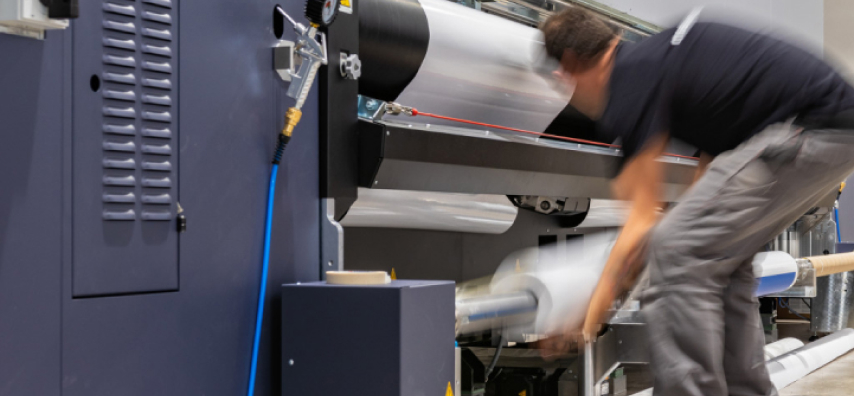

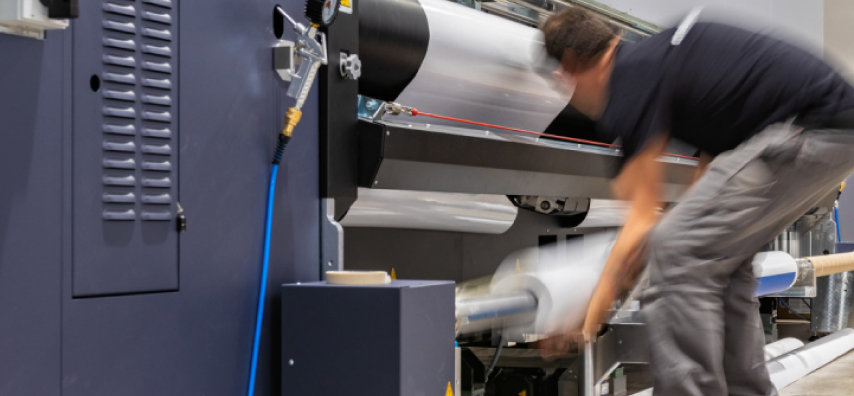

Single/Double Deck High-speed Coater

This equipment is designed for anode and cathode coating processes in lithium-ion battery production, featuring:Closed-loop thickness control for precision coating adjustment;Automatic tape application and roll-to-roll handling;Real-time monitoring of coating dimensions, areal density, and equipment status;Enhanced yield rates and OEE (Overall Equipment Effectiveness) optimization.

Product Feature

-

Intelligentization

Closed-loop control of surface density、MES linkage、PC linkage、AGV linkage、CCD dimension closed-loop、ntelligent maintenance、Automatic cleaning of slot die、Modular bus control

-

Advanced technology

Compatible for both strip, cathode/anode electrode insulation coating process、Dual chamber slot die available for double-layer coating、Large-width substrate coating pre-cutting function (one divides into two)

-

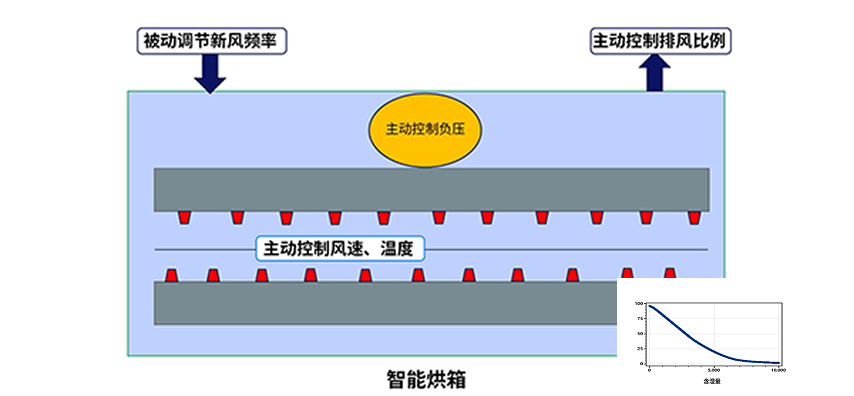

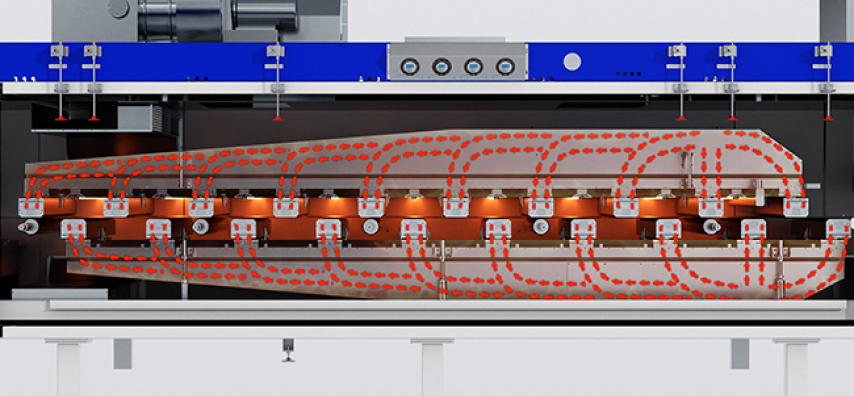

Dryer

Customized nozzle, air volume, air inlet and exhaust layout as per process、Steam, Heat transfer oil, infrared and other combined heating, featuring energy saving and high efficiency、Optimized design according to the simulation of wind and temperature field of dryer、Blast-proof safety design

-

Quality monitoring

Surface density measurement、emperature measurement of electrode surface、Drive roller speed detection、NG marking、NMP concentration detection、Water content detection、CCD monitoring of dimension and appearance、Code scanning of incoming materials

-

Control of copper, metal dust

Copper, zinc and nickel free design where contacting slurry and electrode、Anti-metal friction design of the whole machine、Cutter dust removal、Iron removal and filtration of slurry、Hot air/fresh air filtration、FFU dust compartment

-

Key components

Brand guarantee、Patented structure design, extended service life and convenient maintenance、Some parts are self-made to ensure quality and delivery on schedule

Product Model

-

Equipment type Dimension(L*W*H) Substrate width(mm) Dryer Heating mode KC-SD-800-50.50-A.A 76000*6000*6000 650 50 Heat transfer oil/steam/electric heating KC-SD-1000-50.50-A.A 76000*6200*6000 850 50 Heat transfer oil/steam/electric heating KC-SD-1200-60.60-A.A 86000*6500*6000 1050 60 Heat transfer oil/steam/electric heating KC-SD-1400-60.60-A.A 86000*7000*8500 1250 60 Heat transfer oil/steam/electric heating KC-SD-1600-60.60-A.A 86000*7400*8500 1450 60 Heat transfer oil/steam/electric heating -

Coating product parameters Parameter value Coating method Slot die Coating width MAX:1400mm Coating speed MAX:120m/min Coating dimension accuracy ≤±0.3mm Coating weight accuracy ±1% Coating surface density 5-30mg/cm² Substrate thickness AL 9-20μm/Cu 4.5-20μm Reel diameter/weight MAX:Φ1200mm/3000kg -

Equipment parameters Parameter value Mechanical speed MAX:150m/min Roller width MAX:1600mm Speed accuracy ≤0.05% Coating roller circle run-out ≤1.5μm(Laser measurement) Tension control range 30-500N/±2N Dryer temperature MAX:150℃/±2℃

Correlation Technique

-

Parameter prediction technology of intelligent oven

Parameter prediction technology of intelligent oven -

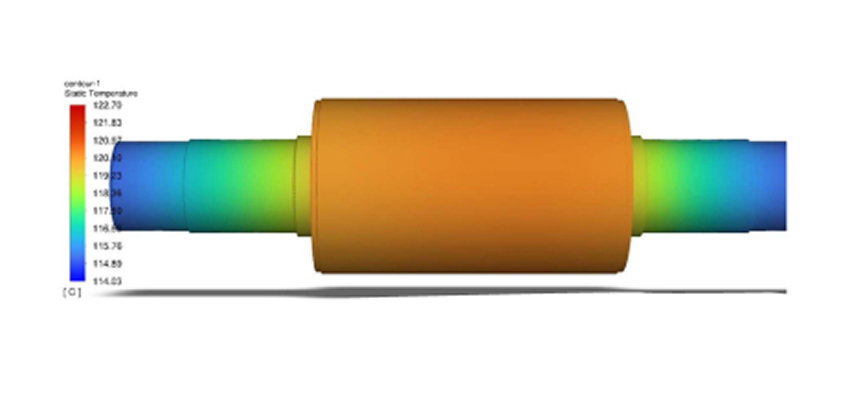

Thermodynamic simulation

Thermodynamic simulation -

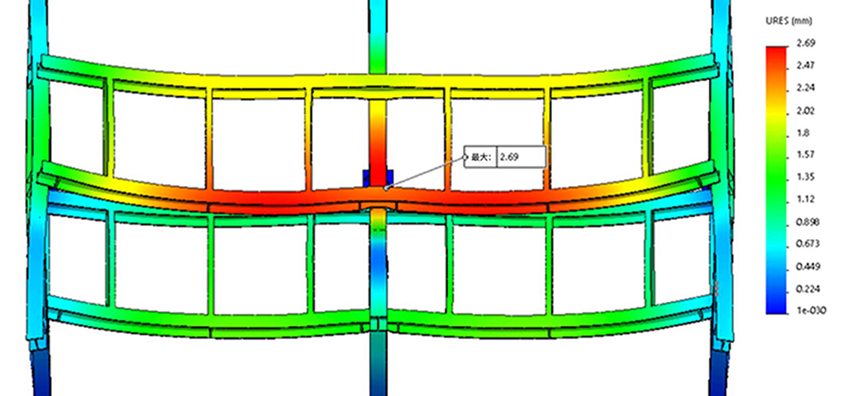

Structural simulation

Structural simulation -

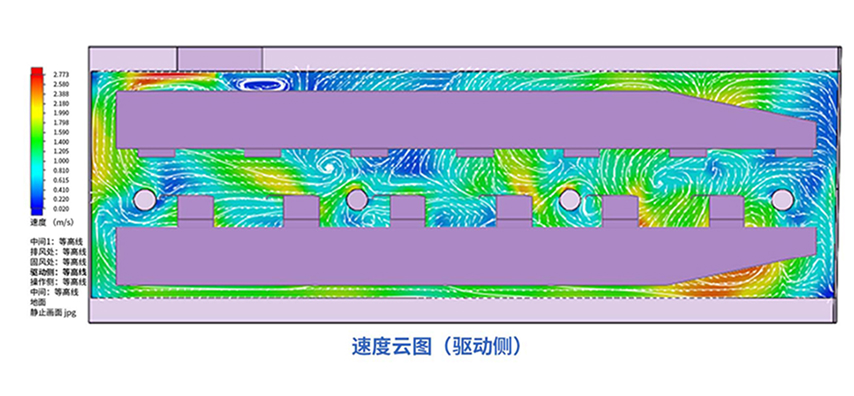

Fluid simulation

Fluid simulation -

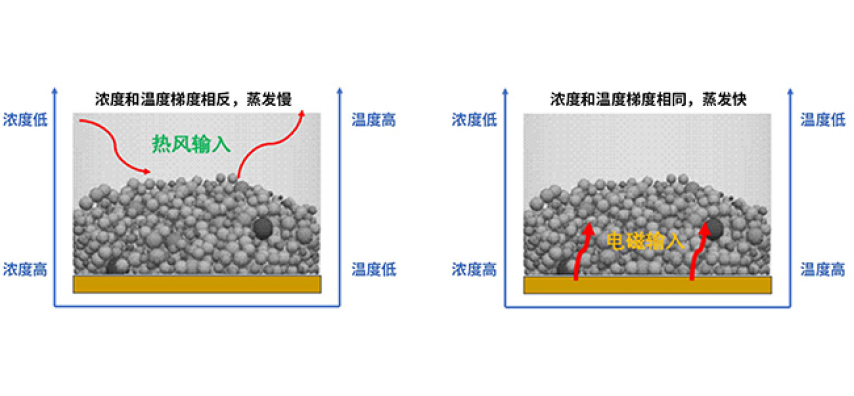

Electromagnetic heating

Electromagnetic heating -

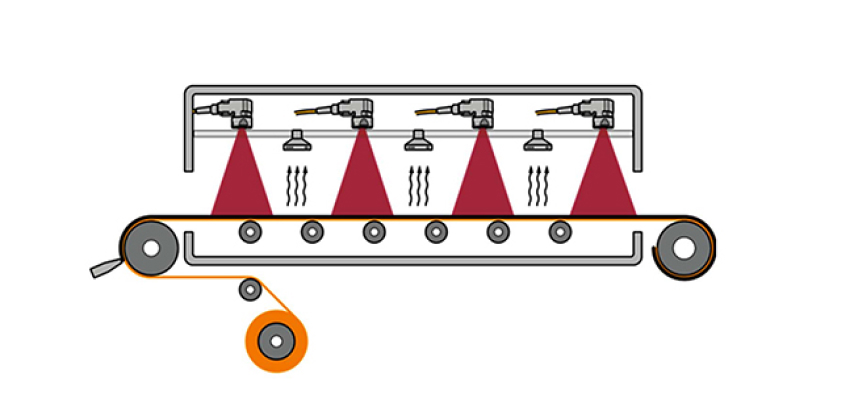

Laser heating

Laser heating -

Infrared Heating

Infrared Heating -

Machine Vision Technology

Machine Vision Technology -

Automatic Misalignment Correction Technology

Automatic Misalignment Correction Technology -

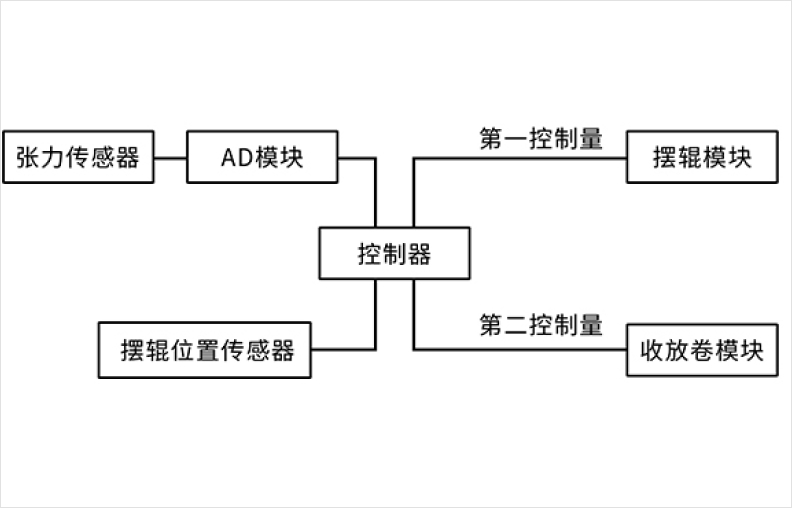

High-precision tension control technology

High-precision tension control technology -

Self-memory

Self-memory -

Self-detection

Self-detection

sales center

-

+86 13622683953

-

Jiangsu KATOP Automation Co., Ltd

-

sales@katopauto.com

sales center

-

+86 13622683953

-

Jiangsu KATOP Automation Co., Ltd

-

sales@katopauto.com